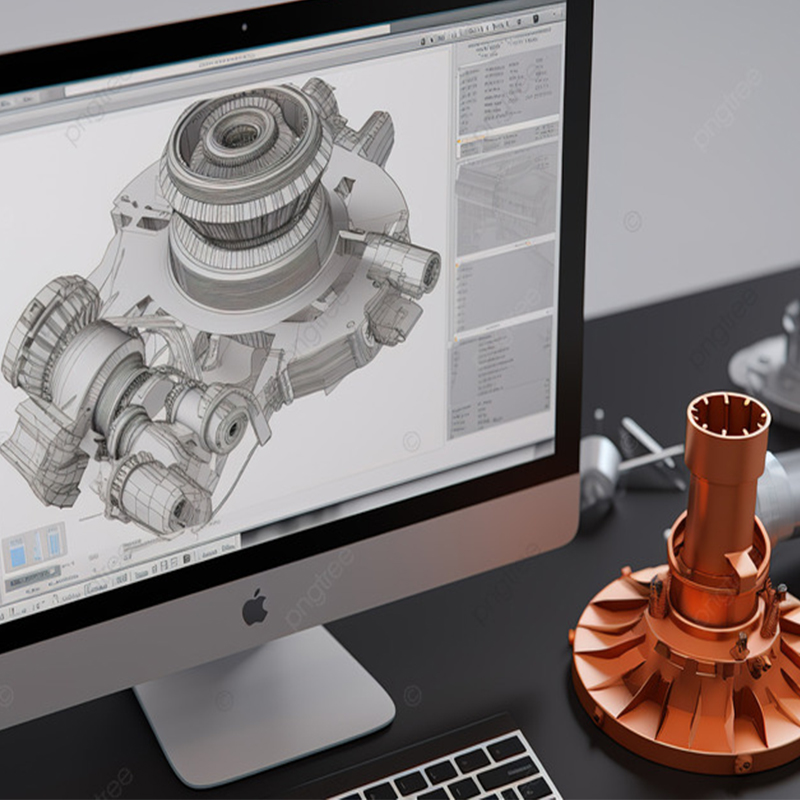

Amasevisi Emishini Yemishini Ye-CNC Yangokwezifiso

Uma udinga izingxenye zomshini wangokwezifiso ezinamajiyometri ayinkimbinkimbi, noma uthole imikhiqizo esetshenziswa ekugcineni ngesikhathi esifushane ngangokunokwenzeka, u-Guan Sheng muhle ngokwanele ukukugqobhoza konke lokho futhi afeze umbono wakho ngokushesha. Sisebenzisa amasethi angaphezu kuka-150 emishini ye-CNC ye-3, 4, kanye ne-5-eksisi, futhi sinikeza izinhlobo ezahlukene ze-100+ zezinto zokwakha kanye nokuqedwa kwendawo, okuqinisekisa ukushintshwa okusheshayo kanye nekhwalithi ye-prototypes eyodwa kanye nezingxenye zokukhiqiza.

I-Die Casting

E-GUAN SHENG Precision, izinsizakalo zethu zokulingisa ukufa ziqukethwe zonke ngaphansi kophahla olulodwa, zilula inqubo yethu futhi zivumela ukulethwa okusheshayo. Sinesipiliyoni seminyaka sikhiqiza izingxenye zensimbi eziphonswe ngokufa ezisezingeni eliphezulu kanye nezingxenye zamakhasimende emhlabeni jikelele. Uma udinga izingxenye zensimbi ezinembile ezenziwe ngevolumu ephansi - xhumana nathi namuhla. Sikulungele ukuphendula noma yimiphi imibuzo ongase ube nayo, sichaze inqubo nezinzuzo zokulingisa ifa, futhi sinikeze isilinganiso samahhala sephrojekthi yakho yokulingisa.

Isevisi yokuphrinta ye-3D

Ukuphrinta kwe-3D kuwubuchwepheshe obungeziwe obusetshenziselwa ukwenza izingxenye. 'Iyengeza' ngoba ayidingi ibhulokhi lento noma isikhunta ukwenza izinto ezibonakalayo, ivele inqwabelene futhi ihlanganise izingqimba zezinto. Ngokuvamile kuyashesha, kunezindleko eziphansi zokusetha okungaguquki, futhi kungakha amajiyometri ayinkimbinkimbi kunobuchwepheshe 'bendabuko', ngohlu oluhlala lunwebeka lwezinto ezibonakalayo. Isetshenziswa kakhulu embonini yobunjiniyela, ikakhulukazi ukwenza i-prototyping nokudala amajiyometri angasindi.

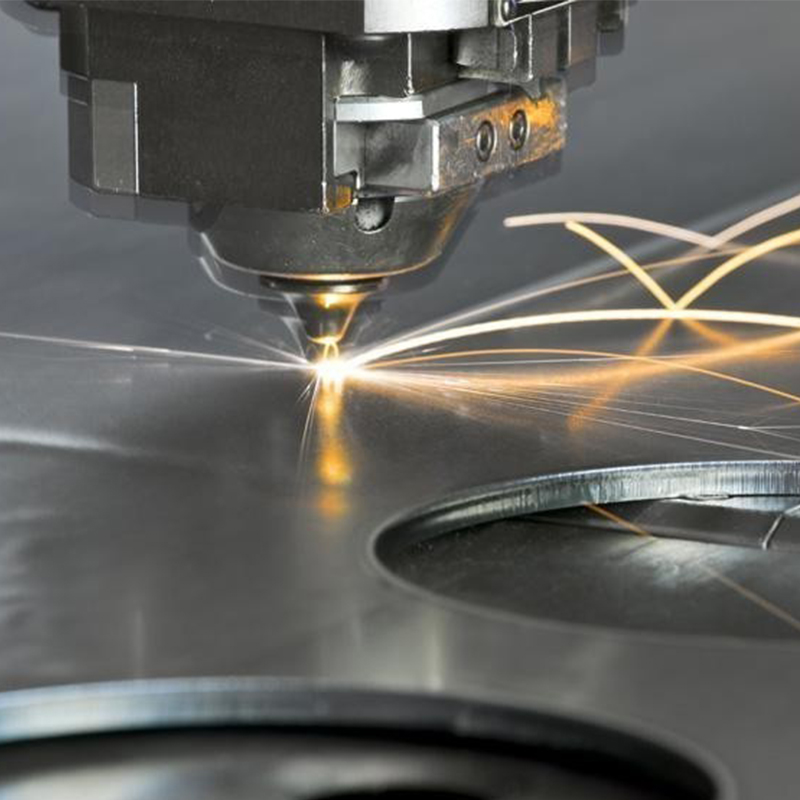

Izinkonzo Zokwenziwa Kwezinsimbi

Njengomhlinzeki wezinsizakalo zokwenziwa kwensimbi yeshidi, i-GUAN SHENG Precision ikhiqiza izitembu eziyinkimbinkimbi, zekhwalithi ephezulu kanye nezinto zokugoba zamakhasimende ngaphakathi nangaphandle. Ukuzinikela kwethu kukhwalithi ehambisana namakhono ethu okwakha abanzi kusenze saphinda amakhasimende endaweni yonke ye-aerospace, ingxenye yezokwelapha, ezokukhiqiza, amandla avuselelekayo, ezezimoto, nezinkambu zokuthuthukisa ikhaya.

Amasevisi Wokuqeda

Izinsizakalo zokuqedela indawo ephezulu yekhwalithi ephezulu zithuthukisa ubuhle bengxenye yakho nemisebenzi ngaphandle kwenqubo yokukhiqiza esetshenzisiwe. Letha ikhwalithi yensimbi, izinhlanganisela, namasevisi okuphothula amapulastiki ukuze uphilise isibonelo noma ingxenye oyiphuphayo.

Ukubunjwa komjovo

Izingxenye zepulasitiki zingenziwa ngezinto ezihlukahlukene ezimangalisayo zezinhlobonhlobo zezinzuzo, ukubekezelelana, namakhono. Igama nezwi, izinkulungwane zezingxenye zepulasitiki zingenziwa kusetshenziswa isikhunta esisodwa, kusheshiswe inqubo yokukhiqiza futhi nokugcina izindleko eziphezulu ziphansi. Ukuze kukhiqizwe ngokushesha izingxenye zepulasitiki akubukeki kukude - Sinikeza izinsizakalo zokubumba umjovo wepulasitiki ezilula zonke ezingaphakathi endlini. Ukubumba umjovo wePlastiki kuyinqubo ekhethwayo yokwakha izingxenye zepulasitiki zangokwezifiso cishe kunoma iyiphi imboni.

I-Silicon Molding

I-Liquid Silicone Rubber (LSR) iyisistimu enezingxenye ezimbili, lapho amaketango amade e-polysiloxane eqiniswa nge-silica ephathwe ngokukhethekile. Ingxenye A iqukethe i-platinum catalyst futhi Ingxenye B iqukethe i-methylhydrogensiloxane njenge-cross-linker kanye ne-alcohol inhibitor. Umehluko oyinhloko phakathi kwerabha ye-liquid silicone (LSR) kanye nerabha ephezulu (HCR) imvelo "egelezayo" noma "ewuketshezi" yezinto ze-LSR. Nakuba i-HCR ingasebenzisa i-peroxide noma inqubo yokwelapha iplatinamu, i-LSR isebenzisa kuphela ukwelapha okunezelwa ngeplatinum. Ngenxa yemvelo ye-thermosetting yezinto ezibonakalayo, ukubumba komjovo werabha ye-silicone ewuketshezi kudinga ukwelashwa okukhethekile, njengokuxutshwa kokusabalalisa okujulile, kuyilapho kugcinwa impahla ezingeni lokushisa eliphansi ngaphambi kokuba iphushwe emgodini oshisayo futhi ivuthwe.