Umkhakha wezokukhiqiza uphakathi kwezimboni ezinamandla kakhulu. Namuhla, kunomfutho ongapheli wokuthuthukisa ukunemba okuphelele nokunemba kanye nezinqubo ezifana ne-EDM yocingo eletha ngokunembile lokho okungeyona into emfushane yokuguqula imboni.

Ngakho-ke, iyiphi i-Wire EDM ngempela, futhi kungani ibhekwa njengenguquko yegeyimu yomkhakha wokukhiqiza? Umbhalo olandelayo uzobheka izinto eziyisisekelo zale ndlela yokukhiqiza eyinkimbinkimbi nezinhlelo zokusebenza kuzo zonke izimboni ezahlukene.

Isingeniso Esifushane ku-Wire EDM

I-Wire Electrical Discharge Machining (EDM) yaphayona ngawo-1940 ngososayensi ababili baseSoviet abaqala ukuguguleka insimbi ngokukhipha ugesi. Ubuchwepheshe bubone intuthuko enkulu ngeminyaka yama-60s kanye nama-80s, budlanga kakhulu kwezohwebo kwezokukhiqiza. Ngasekupheleni kweminyaka yama-90s, ngezithuthukisi ze-IT ne-CNC, imishini ye-EDM yocingo yaba nekhompuyutha kakhulu, yathuthukisa ukusebenza kahle kwayo nokunemba.

Namuhla, i-Wire EDM ibalulekile ezimbonini ezifana ne-Aerospace, Izimoto, kanye Nezokwelapha, ezaziwa ngokuletha imiklamo eyinkimbinkimbi namafomu ayinkimbinkimbi angenakuqhathaniswa nezindlela zemishini zendabuko.

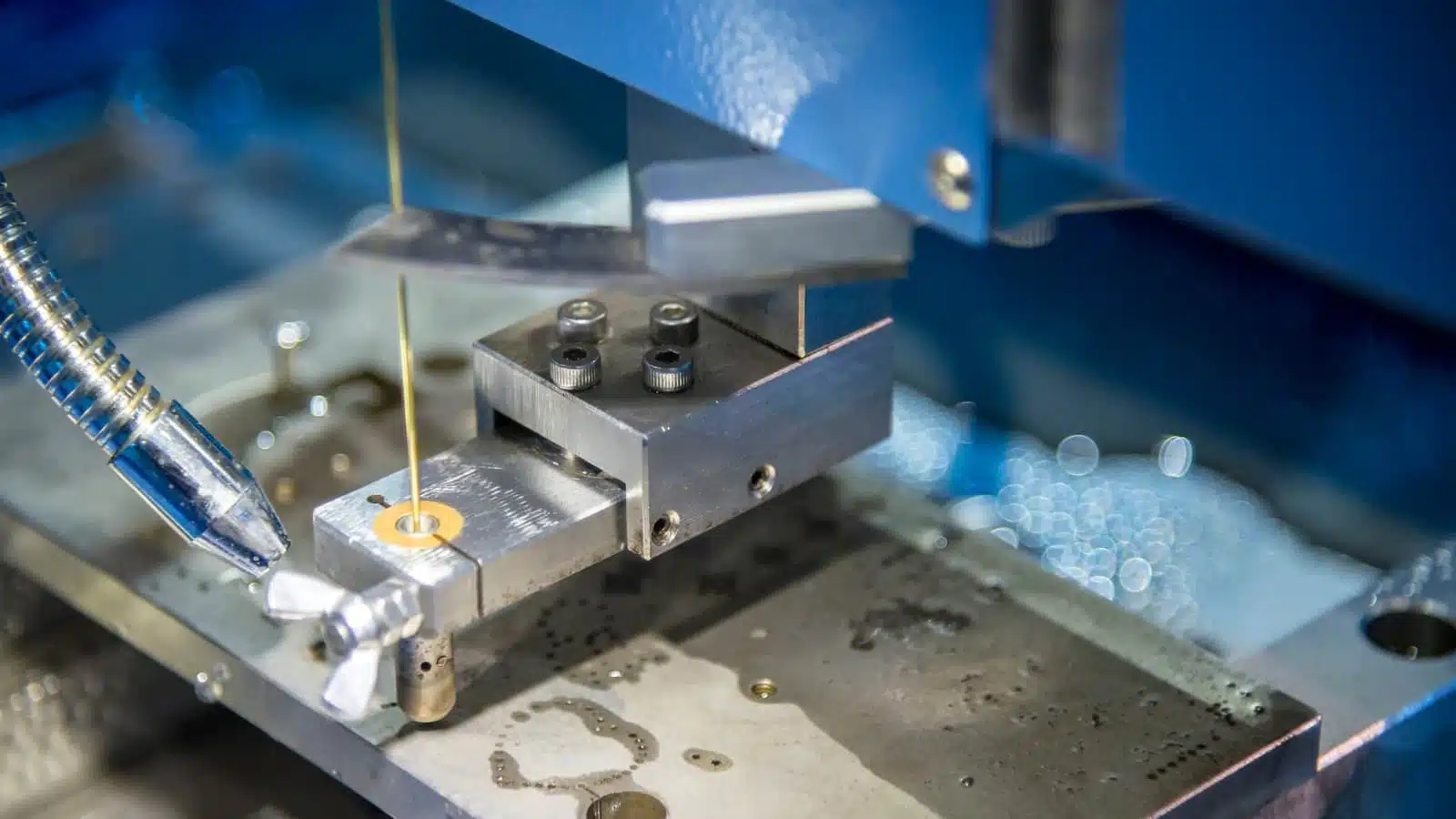

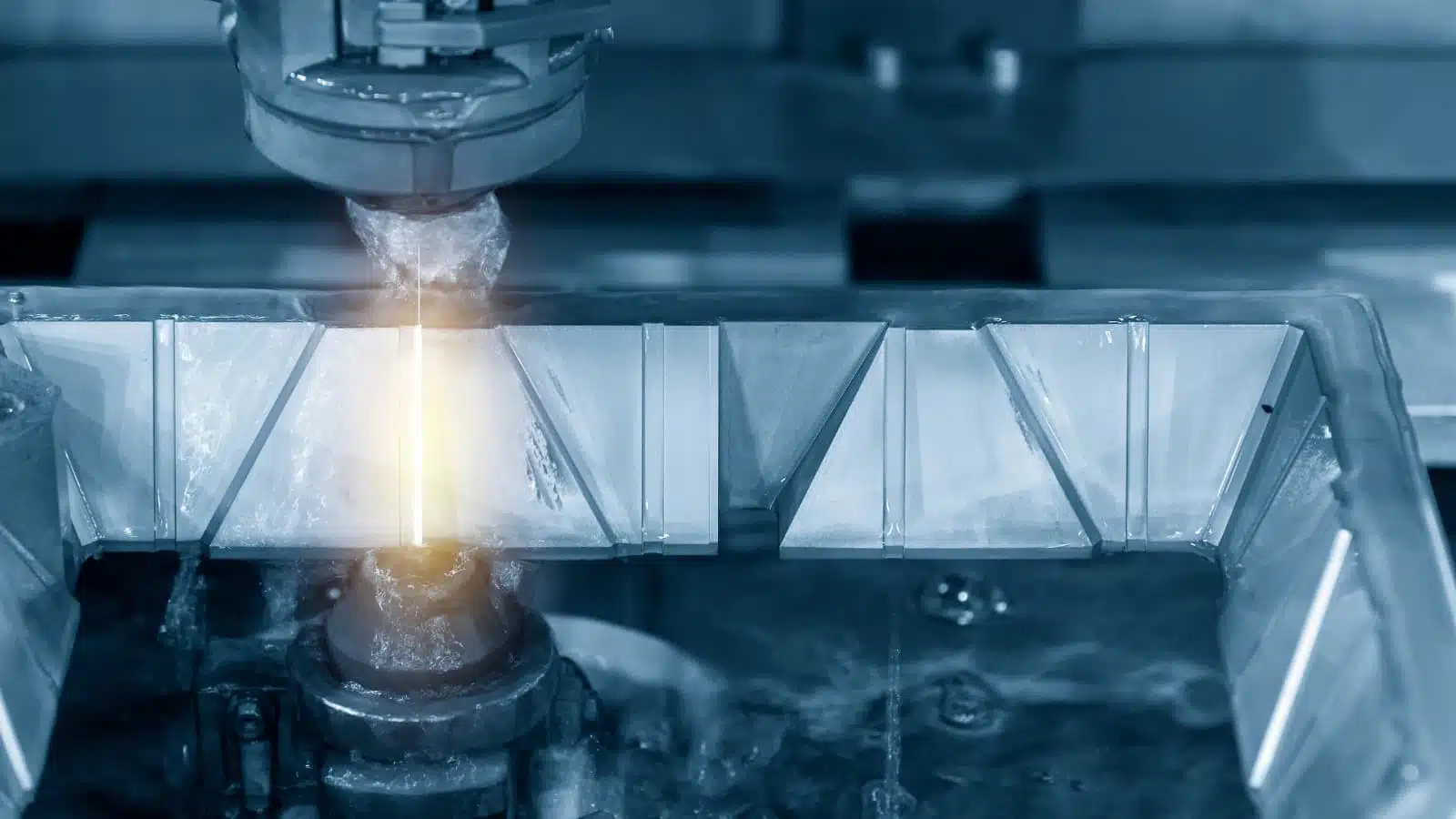

Inqubo ye-EDM yocingo

I-Wire Electrical Discharge Machining (EDM) iyindlela enembayo esebenzisa izinhlansi zikagesi ezilawulwayo ukuncibilikisa izingxenye ezincane zocezu lokusebenza. I-electrode yocingo, ngokuvamile eyenziwe ngezinto zethusi noma ezinamekwe nge-zinc, idala le nhlansi futhi ihamba ngendlela esethwe kusengaphambili. Inzuzo yayo? Isebenza ngaphandle kokuthintana ngokomzimba, ivimbela noma yimuphi umonakalo noma amamaki kukho kokubili ucezu lokusebenza kanye nethuluzi.

Isebenza kanjani i-EDM

I-EDM incike emandleni ashisayo ekuphumeni kukagesi. Lokhu kuphuma kushisa i-workpiece kuze kube yilapho incibilika, yakhe iziteshi ze-plasma ezincane. Lezi ziteshi, ngokuvamile ezinobukhulu be-micrometer, zinganyamalala ngokushesha.

Inqubo ye-EDM yenzeka endaweni ye-dielectric, ngokuvamile amanzi angcolile. Lolu ketshezi lupholisa ucezu lokusebenzela futhi lususe izinto ezihwamukile, lusize ekukhiqizeni okuqhubekayo.

Ukubaluleka kwe-Wire Electrode

Isebenza njenge-cutter kanye ne-conductor, i-electrode yocingo ibalulekile. Imbozwe ngezinto ezifana nethusi noma i-zinc, imelana nokusabela emazingeni okushisa aphezulu. Ilawulwa yikhompyutha, iqinisekisa ukusikeka okunembile ngokuhlanekezela okuncane nokunemba okuphezulu.

Ukubekezelelwa kwe-Wire EDM

Ukusika ngocingo kuphakathi kwezinqubo zokukhiqiza ezinembe kakhulu ezikhona. Ngakho-ke, ukubekezelelana okuqinile akukhona okujwayelekile kukho. Ukubekezelelana kwangempela kuncike ezicini eziningana ezihlanganisa ubunkimbinkimbi bephrojekthi, amakhono okwenza imishini, namakhono omqhubi.

Kodwa-ke, ukubekezelelana okujwayelekile nokwamukelekayo kuwuphawu lwemboni olulandelwa abakhiqizi abaningi.

Ukubekezelelana Okujwayelekile Nokubekezelelana Okuhle

Ukubekezelelana Okujwayelekile

Ukubekezelelwa Komugqa: Ngokuvamile isukela ku-±0.005 kuya ku-±0.001 amayintshi (0.127 kuya ku-0.0254 mm), okubonisa ukuchezuka okuvunyelwe kwezici ezifana nezimbobo, izikhala, noma amaphrofayela.

Ukubekezelela Ububanzi Bembobo: Ngokuvamile phakathi kwamayintshi angu-±0.0005 kuya ku-±0.001 (0.0127 kuya ku-0.0254 mm), ukuqinisekisa ukuthi izimbobo ezinomshini zihlala ngaphakathi kobubanzi obuchaziwe.

Ukubekezelelana Okuhle

Ukubekezelelwa Komugqa: Ifinyelela ukunemba ezingeni le-micron, ngokuvamile ukusuka ku-±0.0002 kuya ku-±0.0001 amayintshi (0.0051 kuya ku-0.00254 mm), okubalulekile ezinhlelweni zokusebenza ezidinga ukunemba okukhulu.

Ukubekezelela Ububanzi Bembobo: Ububanzi busuka ku-±0.0001 kuya ku-±0.00005 amayintshi (0.00254 kuya ku-0.00127 mm), okugqamisa ukunemba okukhethekile kwe-Wire EDM.

Izinto Ezithinta Ukubekezelelana ku-Wire EDM

I-Wire EDM idume ngokunemba kwezinga layo le-micron, okuyenza ilungele izinhlelo zokusebenza eziyinkimbinkimbi. Nokho, ukunemba kwayo akulungisiwe futhi kuncike ezintweni ezimbalwa:

• Ukuzinza Komshini: Umshini ozinzile uqinisekisa ukunemba okungcono ezenzweni zokusika.

•Ikhwalithi Nobubanzi Bentambo: Ukuhlanzeka kwayo, ububanzi, nezici zikagesi kuthonya inqubo yokwenza imishini. Imiphumela emihle idinga ibhalansi phakathi kwekhwalithi yentambo nobubanzi.

•I-Workpiece Material: Nakuba ezinye izinto zokusebenza zifinyeleleka kalula emishinini, ukukhetha kwezinto ezibonakalayo kufanele kuhambisane nezidingo zohlelo lokusebenza.

•Izimo Ze-Flush: Ukugeleza kwe-dielectric medium, kuthinta ikhwalithi yenqubo yomshini, izinsiza ekususeni impahla, ukukhishwa kukagesi okungaguquki, kanye nokukhipha ukushisa okuphumelelayo.

•Ukulinganiswa Nokunakekelwa Komshini: Amakhono omshini abalulekile. Imishini ephakeme enabasebenzi abanolwazi ibalulekile ukuze kuzuzwe ukubekezelelana okungcono kakhulu.

•Ukuzinza Kokushisa: Ukugcina ukunemba okwaziwayo kwe-Wire EDM, ama-arcs kagesi alawulwayo abalulekile. Ukungasebenzi kahle kwe-thermal kungabeka engcupheni ukunemba, kugcizelela ukubaluleka kwezimo ezingaguquki.

Izinto Ezifaneleka Kakhulu Zokusika Ngocingo

Izinsimbi Ezisansimbi

Insimbi engagqwali

Ihlanganisa ukuqina ne-conductivity kagesi enhle kakhulu. Ikhono layo lokumelana nokugqwala liyenza ibe yinto efunwa kakhulu ezimbonini ezihlukahlukene. Kumongo wokwenza imishini, ukuhambisana kwayo nemiklamo enembile nenemininingwane kuyagqama.

Insimbi Yensimbi

Idume ngezici zayo eziqinile, insimbi yamathuluzi iwumgogodla wamathuluzi amaningi esindayo nezingxenye ezinembayo. Ukuqina kwayo okungokwemvelo, uma kuhlanganiswa nezakhiwo zayo zikagesi, kuyenza ibe ikhandidethi eliyinhloko lemininingwane eyinkimbinkimbi nobukhali obuhlala isikhathi eside.

Insimbi Yekhabhoni

Isidlali esishintshashintshashintshayo esizindeni sensimbi, i-carbon steel, nakuba ikwazi ukusebenza kancane kunozakwabo, ingenziwa ifaneleke ngokufaneleka ngezinketho ezifanele zama-electrode namapharamitha okusebenza. Ukufinyeleleka kwayo kuhlangene nokusebenza kwayo kuyenza ibe yisisekelo ezimbonini eziningi.

I-alloy Steel

Ukuhlanganiswa kwezakhi, ukusebenza kwensimbi ye-alloy kuyi-tapestry yezingxenye zayo. Ngokuya ngenhlanganisela yayo ehlukile, inganikeza amandla, ukuqina, kanye nokusebenza kanzima, ikwenze kube ukukhetha okuguquguqukayo kwezinhlelo zokusebenza ezihlukahlukene.

Izinsimbi Ezingeyona Insimbi

I-Titanium

Okuvame ukubizwa ngokuthi 'insimbi yeminyaka yobudala', ukuqina kwe-titanium nendawo encibilika kakhulu kubangela izinselele ekwenzeni imishini evamile. Kodwa-ke, lapho icwecwe ngamathuluzi anembayo, iveza imiklamo eyinkimbinkimbi futhi eqinile, okuyenza ibe intandokazi ezimbonini ze-aerospace nezimboni zezokwelapha.

I-Aluminium

Intandokazi yezinsimbi ezingasindi, i-aluminium ibungazwa ngokusebenza kwayo okuhle kukagesi nokungabi lula. Ayinikezi nje kuphela ukukhululeka komshini kodwa futhi ithembisa amandla ngaphandle komthwalo wesisindo, okwenza kube semqoka ezimbonini kusukela kwezokuthutha kuye ekupakishweni.

Ithusi

I-conductor par excellence, ithusi isenhliziyweni yezimangaliso eziningi zikagesi neze-elekthronikhi. Umbala wayo wemvelo obomvu-wolintshi uhlanganiswe nekhono layo lokubumba izingxenye ezinemininingwane kuwenza ubaluleke kakhulu kukho konke kusukela kogesi kuya kwezobuciko bokuhlobisa.

Ithusi neBronze

Lawa ma-alloys, akhazimula ngamathoni awo egolide, awawona nje ama-aesthetics. Izici zabo zikagesi ezitusekayo zibenza baye ezintweni zokwakha lapho ukunemba kuhlangabezana nobuhle, njengakubucwebe obuhlotshisiwe noma izingxenye ze-elekthronikhi ezenziwe kahle.

Izicelo Ezibalulekile ze-Wire EDM ku-Modern Engineering

Imishini ye-EDM yocingo izuza amandla ngenxa yokuguquguquka kwayo ekuphatheni izinto ezihlukahlukene kanye nekhono layo lokuthola imininingwane enembile nokubekezelela okuqinile, okuyenza ibe semqoka ekukhiqizeni kwesimanje. Nazi izinhlelo zokusebenza ezintathu eziyinhloko:

Ukunemba Kwezingxenye Zokukhiqiza

Inketho evamile yokukhiqiza izingxenye ezinemba okuphezulu ezinokubekezelelana okuqinile. Isebenza kahle kakhulu ekukhiqizeni izimo eziyinkimbinkimbi, imininingwane emihle, nezici ezincane ezintweni ezihlukahlukene.

Izimboni ezifana ne-aerospace, medical, automotive, ne-electronics zithembele ku-Wire EDM ukuze zenze izingxenye ezibalulekile njengamagiya, imibhobho, izixhumi, nezibungu eziyinkimbinkimbi.

Ithuluzi kanye ne-Die Production

I-Wire EDM ibalulekile ekwakheni isikhunta, i-dies, kanye namathuluzi akhethekile, ihlinzeka ngezinqubo kusukela ekubunjweni komjovo kuya ekugxivizeni. Amandla endlela ekuphakamiseni ubukhulu obuqondile nokubaza ama-engeli abukhali aqinisekisa ikhwalithi ye-premium nokufana ekukhiqizeni ngezinga elikhulu.

Ukuthuthukiswa Kwesibonelo

Ukuze uthole i-prototyping esheshayo nenembayo, onjiniyela nabasunguli badonsela ku-Wire EDM. Lokhu kusheshisa ukuqinisekiswa kwedizayini nezigaba zokuhlola ezinzima.

Ama-prototypes acwecwe nge-Wire EDM afanekisela umkhiqizo wokugcina, egcizelela ukubaluleka kwawo emjikelezweni wokuvela komkhiqizo.

Uma kubhekwa amandla ayo kulezi zindawo ezibalulekile, amakhono anemba nanembile we-Wire EDM asetshenziswa kabanzi ezimbonini eziningi.

•Medical Device Manufacturing

•Ezogesi kanye nezingxenye ezincane

•I-Aerospace kanye ne-Aviation

•Ubucwebe kanye nokwenza iwashi

•Imboni Yezimoto

•Umkhakha wezaMandla

•Ukulungisa Isikhunta kanye Nokufa

Isikhathi sokuthumela: Dec-12-2023