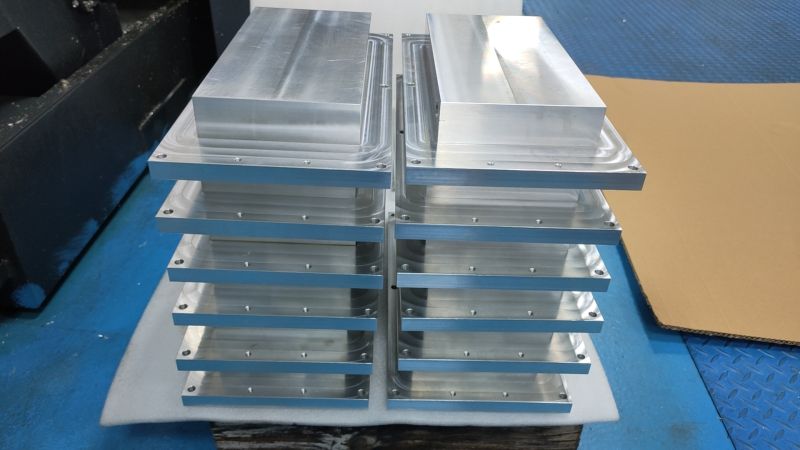

Sisanda kwenza iqoqo elincaneIzingxenye ze-CNC ezenziwe ngokwezifiso. Enqubweni yokucubungula iqoqo, siqinisekisa kanjani ukunemba kwayo yonke inqwaba yezingxenye?Ekukhiqizweni ngobuningi kwezingxenye ze-CNC, ukuqinisekisa ukusebenza kahle nokunemba kungaqala ezicini ezilandelayo.

Ukuze usebenze kahle, eyokuqala wuhlelo olufanele.

Indlela yamathuluzi ithuthukiswa ngesikhathi sokuhlela ukunciphisa ukuhamba okungenalutho kanye nezenzo zokusika ezingadingekile, ukuze ithuluzi licutshungulwe ngendlela esheshayo neqondile. Isibonelo, uma izindawo zokugaya, amasu okugaya asebenzayo, afana nokugaya ngezindlela ezimbili, anganciphisa isikhathi sokunyakaza kwamathuluzi ngaphandle kwendawo yokucubungula. Okwesibili ukukhetha kwamathuluzi. Ngokwengxenye yempahla kanye nezidingo zokwenza, khetha ithuluzi elifanele kanye nohlobo lwamathuluzi. Isibonelo, lapho ucubungula izingxenye ze-aluminium alloy, ukusetshenziswa kwamathuluzi ensimbi anesivinini esikhulu kungathuthukisa isivinini sokusika, ngaleyo ndlela kuthuthukise ukusebenza kahle kokucubungula. Ngaphezu kwalokho, kuyadingeka ukuqinisekisa impilo yesevisi yethuluzi, esikhundleni sethuluzi eligugile ngesikhathi, futhi ugweme ukwehla kwesivinini sokucubungula ngenxa yokugqoka kwamathuluzi. Ngaphezu kwalokho, ukuhlelwa okunengqondo kwezinqubo zokucubungula nakho kubaluleke kakhulu. Faka phakathi uhlobo olufanayo lokucubungula ukuze unciphise inani lezikhathi zokubopha, isibonelo, yonke imisebenzi yokugaya ingenziwa kuqala, bese kuba imisebenzi yokumba. Ngesikhathi esifanayo, ukusetshenziswa kwedivayisi yokulayisha nokukhipha okuzenzakalelayo kunganciphisa isikhathi sokulayisha nokulayisha ngesandla, ukufeza ukucubungula okungaphazanyiswa kwethuluzi lomshini, futhi kuthuthukise ukusebenza kahle konke.

Esicini sokuqinisekisa ukunemba, ukugcinwa kokunemba kwamathuluzi omshini kuwukhiye.

Kudingekile ukuhlola nokulinganisa ithuluzi lomshini njalo, okuhlanganisa ukunemba kokuma kwezimbazo zokuxhumanisa nokunemba kokuma okuphindaphindiwe. Isibonelo, i-laser interferometer isetshenziselwa ukulinganisa i-eksisi yethuluzi lomshini ukuqinisekisa ukunemba kokunyakaza kwethuluzi lomshini. Futhi ukuzinza kwe-clamping nakho kubaluleke kakhulu, khetha ukulungiswa okulungile ukuze uqinisekise ukuthi izingxenye ngeke zisuswe ngesikhathi sokucubungula. Isibonelo, lapho ucubungula izingxenye ze-shaft, ukusetshenziswa kwe-chuck yemihlathi emithathu nokuqinisekisa ukuthi amandla ayo okubamba afanelekile kungavimbela ngokuphumelelayo izingxenye ekuphumeni kwe-radial phakathi nokucubungula okujikelezayo. Ngaphezu kwalokho, ukunemba kwethuluzi akukwazi ukushaywa indiva. Sebenzisa amathuluzi anemba okuphezulu, futhi uqinisekise ukunemba kokufaka lapho ithuluzi lifakiwe, njengalapho ufaka i-drill, ukuze uqinisekise idigri ye-coaxial ye-drill kanye ne-spindle yomshini. Ngaphezu kwalokho, isinxephezelo ngesikhathi sokucubungula siyadingeka. Isistimu yokulinganisa iqapha usayizi womshini wezingxenye ngesikhathi sangempela, bese inxephezela iphutha lomshini ngomsebenzi wokunxephezela wesistimu ye-CNC ukuze kuqinisekiswe ukunemba kobukhulu bezingxenye.

Isikhathi sokuthumela: Dec-27-2024