Ukuboniswa okuvamile komshini we-CNC, izikhathi eziningi, kuhilela ukusebenza ngocezu lwensimbi oluyinsimbi. Kodwa-ke, akukhona nje kuphela ukuthi umshini we-CNC osebenza kabanzi kumapulasitiki, kodwa ukwenziwa kwe-plastic CNC kungenye yezinqubo ezivamile zokunyathelisa ezimbonini eziningana.

Ukwamukelwa komshini wepulasitiki njengenqubo yokukhiqiza kungenxa yohlu olubanzi lwezinto zepulasitiki ze-CNC ezitholakalayo. Ngaphezu kwalokho, ngokwethulwa kokulawulwa kwezinombolo zekhompuyutha, inqubo iba enembe kakhulu, isheshe, futhi ifanele ukwenza izingxenye ezinokubekezelela okuqinile. Kungakanani okwaziyo mayelana ne-plastic CNC machining? Lesi sihloko sidingida izinto ezihambisana nenqubo, amasu atholakalayo, nezinye izinto ezingasiza iphrojekthi yakho.

Ipulasitiki ye-CNC Machining

Amapulasitiki amaningi asebenza ngomshini afanele ukukhiqiza izingxenye kanye nemikhiqizo ekhiqizwa izimboni eziningana. Ukusetshenziswa kwazo kuncike ezimpahleni zazo, ngamapulasitiki athile asebenzisekayo, njengenayiloni, anezici ezinhle kakhulu zemishini ezivumela ukuthi zithathe indawo yensimbi. Ngezansi amapulasitiki avame kakhulu okwenziwa ngokwezifiso zepulasitiki:

I-ABS:

I-Acrylonitrile Butadiene Styrene, noma i-ABS, iyinto engasindi ye-CNC eyaziwa ngokumelana nomthelela, amandla, kanye nokusebenziseka kalula. Nakuba inezici ezinhle zokuwumshini, ukusimama kwayo okuncane kwamakhemikhali kubonakala ekuthambekeni kwayo kalula kumafutha, uphuzo oludakayo, nezinye izincibilikisi zamakhemikhali. Futhi, ukuzinza okushisayo kwe-ABS ehlanzekile (okungukuthi, i-ABS ngaphandle kwezithasiselo) iphansi, njengoba i-polymer yepulasitiki izoshisa ngisho nangemva kokukhipha ilangabi.

Izinzuzo

Ilula ngaphandle kokulahlekelwa amandla ayo omshini.

I-polymer yepulasitiki isebenziseka kalula, iyenza ibe yinto ethandwa kakhulu yokukopisha ngokushesha.

I-ABS inephuzu elincibilikayo eliphansi elifanele (lokhu kubalulekile kwezinye izinqubo ze-prototyping ezisheshayo njengokuphrinta kwe-3D nokubumba umjovo).

Inamandla aphezulu okudonsa.

I-ABS inokuqina okuphezulu, okusho ubude bempilo ende.

Iyathengeka.

Ububi

Ikhipha intuthu yepulasitiki eshisayo uma ingaphansi kokushisa.

Udinga ukungena komoya ngendlela efanele ukuze uvimbele ukunqwabelana kwamagesi anjalo.

Inephuzu elincibilikayo eliphansi elingabangela ukuguquguquka ekushiseni okukhiqizwa umshini we-CNC.

Izinhlelo zokusebenza

I-ABS iyi-thermoplastic yobunjiniyela ethandwa kakhulu esetshenziswa izinsizakalo eziningi ze-prototyping ezisheshayo ekwenzeni imikhiqizo ngenxa yezakhiwo zayo ezinhle kakhulu nokufinyeleleka kwayo. Kusebenza ezimbonini zikagesi nezezimoto ekwenzeni izingxenye ezifana namakepisi ekhibhodi, izindawo ezivalekile zikagesi, nezingxenye zedeshibhodi yemoto.

Inayiloni

Inayiloni noma i-polyamide iyi-polymer yepulasitiki enokungqubuzana okuphansi enomthelela ophezulu, amakhemikhali, kanye nokumelana nokuhuzuka. Izakhiwo zayo ezinhle kakhulu zemishini, njengamandla (76mPa), ukuqina, nobulukhuni (116R), ziyenza ifaneleke kakhulu ukwenziwa kwemishini ye-CNC futhi ithuthukise kakhulu ukusetshenziswa kwayo embonini yezimoto nengxenye yezokwelapha.

Izinzuzo

Izakhiwo ezinhle kakhulu zemishini.

Inamandla aphezulu okudonsa.

Kuqiza kahle.

I-polymer engasindi.

Iyakwazi ukumelana nokushisa namakhemikhali.

Ububi

Inokuqina kwe-dimensional ephansi.

Inayiloni ingathatha umswakama kalula.

Kungenwa kalula kuma-acid amaminerali aqinile.

Izinhlelo zokusebenza

Inayiloni iyi-thermoplastic yobunjiniyela esebenza kahle kakhulu esebenza ku-prototyping nokukhiqiza izingxenye zangempela embonini yezokwelapha neyezimoto. Ingxenye eyenziwe ngezinto ze-CNC ihlanganisa ama-bearing, amawasha, namashubhu.

I-Acrylic

I-Acrylic noma i-PMMA (i-Poly Methyl Methacrylate) idumile kuma-plastic CNC machining ngenxa yezindawo zayo zokubona. I-polymer yepulasitiki iyakwazi ukuguquguquka futhi imelana nokuklwebheka, yingakho ukusetshenziswa kwayo ezimbonini ezidinga lezi zakhiwo. Ngaphandle kwalokho, inezakhiwo ezinhle kakhulu zemishini, okubonakala ngokuqina kwayo kanye nokumelana nomthelela. Ngokushibhile kwayo, umshini we-acrylic CNC usuphenduke enye indlela yama-polymer epulasitiki njenge-polycarbonate nengilazi.

Izinzuzo

Ayisindi.

I-Acrylic inamakhemikhali amaningi futhi imelana ne-UV.

Inokusebenza okuphezulu.

I-Acrylic inokumelana namakhemikhali aphezulu.

Ububi

Akukona lokho ukumelana nokushisa, umthelela, nokuhuzuka.

Ingaqhekeka ngaphansi komthwalo osindayo.

Ayimelani nezinto eziphilayo ezine-chlorinated/aromatic.

Izinhlelo zokusebenza

I-Acrylic iyasebenza ekushintsheni izinto ezifana ne-polycarbonate nengilazi. Ngenxa yalokho, iyasebenza embonini yezimoto ekwenzeni amapayipi alula kanye nesembozo sokukhanya kwezinkomba zemoto nakwezinye izimboni zokwenza amaphaneli elanga, ama-greenhouse canopies, njll.

I-POM

I-POM noma i-Delrin (igama lezentengiselwano) iyimpahla yepulasitiki ye-CNC esebenziseka kalula ekhethwe izinsizakalo eziningi zemishini ye-CNC ngenxa yamandla ayo aphezulu kanye nokumelana nokushisa, amakhemikhali, nokuguga/ukudabuka. Kunamabanga amaningana e-Delrin, kodwa izimboni eziningi zithembele ku-Delrin 150 no-570 njengoba zizinzile ngokwengxenye.

Izinzuzo

Ziyakwazi machable kunazo zonke CNC plastic materials.

Ziyakwazi ukumelana namakhemikhali okuhle kakhulu.

Zinokuqina okuphezulu kwe-dimensional.

Inamandla aphezulu okuqina nokuqina, iqinisekisa isikhathi eside sokuphila.

Ububi

Inokumelana kabi nama-asidi.

Izinhlelo zokusebenza

I-POM ithola ukusetshenziswa kwayo kuzo zonke izimboni ezihlukahlukene. Isibonelo, emkhakheni wezimoto, isetshenziselwa ukwakha izingxenye zebhande lesihlalo. Imboni yemishini yezokwelapha iyisebenzisela ukukhiqiza amapeni e-insulin, kanti umkhakha wezimpahla zabathengi usebenzisa i-POM ukwenza ugwayi we-elekthronikhi namamitha amanzi.

I-HDPE

Ipulasitiki ye-polyethylene ene-high-density iyi-thermoplastic ekwazi ukumelana nokucindezeleka namakhemikhali abolayo. Ihlinzeka ngezakhiwo ezinhle kakhulu zemishini njengamandla e-tensile (4000PSI) nokuqina (R65) kunozakwabo, i-LDPE efaka esikhundleni sayo ezinhlelweni ezinezidingo ezinjalo.

Izinzuzo

Kuyipulasitiki eguquguqukayo ekwazi ukusebenziseka kalula.

Imelana kakhulu nokucindezeleka kanye namakhemikhali.

Inezici ezinhle kakhulu zemishini.

I-ABS inokuqina okuphezulu, okusho ubude bempilo ende.

Ububi

Inokumelana ne-UV okungekuhle.

Izinhlelo zokusebenza

I-HDPE Inezinhlelo zokusebenza ezihlukahlukene, okuhlanganisa ukwenza i-prototyping, ukudala amagiya, ama-bearings, ukupakisha, ukufakwa kukagesi, kanye nemishini yezokwelapha. Ilungele ukwenza i-prototyping njengoba ingenziwa ngomshini ngokushesha futhi kalula, futhi izindleko zayo eziphansi ziyenza ibe yinhle kakhulu ekudaleni ukuphindaphinda okuningi. Ngaphandle kwalokho, iyimpahla ekahle yamagiya ngenxa ye-coefficient ephansi yokungqubuzana nokumelana nokugqokwa okuphezulu, kanye nama-bearings, ngoba iyazithambisa futhi imelana namakhemikhali.

I-LDPE

I-LDPE iyi-polymer yepulasitiki eqinile, eguquguqukayo enokumelana okuhle kwamakhemikhali kanye nezinga lokushisa eliphansi. Isebenza kakhulu embonini yokukhiqiza ingxenye yezokwelapha ekwenzeni ama-prosthetics nama-orthotics.

Izinzuzo

Iqinile futhi iyavumelana nezimo.

Iyakwazi ukumelana nokugqwala.

Kulula ukuvala usebenzisa amasu okushisa njenge-welding.

Ububi

Ayifaneleki izingxenye ezidinga ukumelana nezinga lokushisa eliphezulu.

Inokuqina okuphansi namandla esakhiwo.

Izinhlelo zokusebenza

I-LDPE ivamise ukusetshenziselwa ukukhiqiza amagiya enziwe ngokwezifiso kanye nezingxenye zemishini, izakhi zikagesi njengezivikeli nezindlu zemishini kagesi, nezingxenye ezinokubukeka okupholishiwe noma okucwebezelayo. Yini enye. I-coefficient yayo ephansi yokungqubuzana, ukumelana nokufakwa okuphezulu kwe-insulation, nokuqina kuyenza ibe into efanelekile yezinhlelo zokusebenza ezisebenza kahle kakhulu.

I-Polycarbonate

I-PC iyi-polymer yepulasitiki eqinile kodwa engasindi enezinto ezivimbela ukushisa kanye nezakhiwo zikagesi zokuvikela ukushisa. Njenge-acrylic, ingashintsha ingilazi ngenxa yokubonakala kwayo kwemvelo.

Izinzuzo

Isebenza kahle kakhulu kuneningi le-thermoplastic yobunjiniyela.

Ibonisa ngale ngokwemvelo futhi ingadlulisela ukukhanya.

Kuthatha umbala kahle kakhulu.

Inamandla aphezulu okuqina nokuqina.

I-PC imelana nama-asidi ahlanjululwe, amafutha, namafutha.

Ububi

Yehla ngemva kokuchayeka isikhathi eside emanzini angaphezu kuka-60°C.

Iyakwazi ukugqoka i-hydrocarbon.

Izobaphuzi ngokuhamba kwesikhathi ngemva kokuchayeka isikhathi eside emisebeni ye-UV.

Izinhlelo zokusebenza

Ngokusekelwe ezicini zayo ezikhanyayo, i-polycarbonate ingashintsha izinto zengilazi. Ngakho-ke, isetshenziswa ekwenzeni izibuko zokuphepha nama-CD/DVDs. Ngaphandle kwalokho, ilungele ukwenza amathuluzi okuhlinza nama-circuit breaker.

Plastic CNC Machining Izindlela

I-CNC plastic part machining ihlanganisa ukusebenzisa umshini olawulwa ngekhompuyutha ukususa ingxenye ye-polymer yepulasitiki ukwenza umkhiqizo owufunayo. Inqubo yokukhiqiza ekhiphayo ingakha izinkulungwane zezingxenye ezinokubekezelela okuqinile, ukufana, nokunemba kusetshenziswa izindlela ezilandelayo.

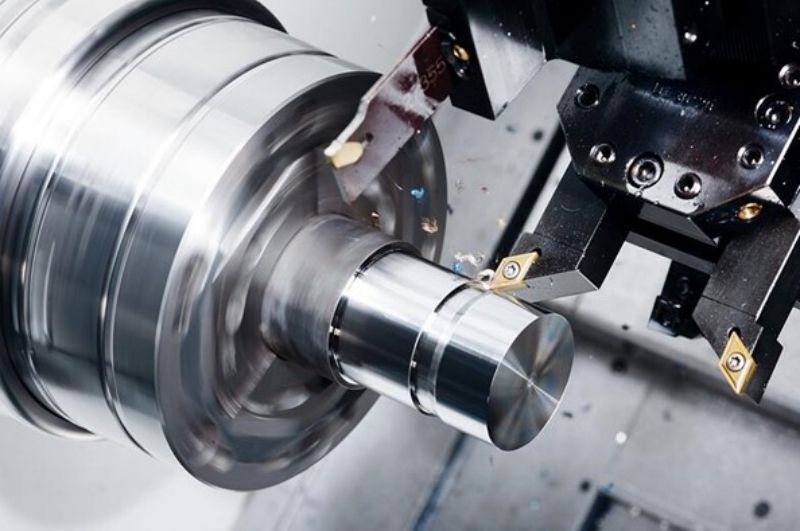

Ukuphenduka kwe-CNC

I-CNC Turning iwubucwepheshe bomshini obuhlanganisa ukubamba ucezu lokusebenza emshinini wokusebenza bese uwuzungezisa ngokumelene nethuluzi lokusika ngokuphotha noma ukujika. Kukhona futhi izinhlobo eziningana zokuphenduka kwe-CNC, okuhlanganisa:

Ukujika kwe-CNC okuqondile noma okuyisilinda kulungele ukusikeka okukhulu.

Ukuphenduka kwe-Taper CNC kulungele ukudala izingxenye ezinomumo ofana nekhoni.

Kunemihlahlandlela eminingana ongayisebenzisa ekuguquleni i-plastic CNC, okuhlanganisa:

Qinisekisa ukuthi amaphethelo anegegethi emuva ukuze unciphise ukuhlikihla.

Imiphetho yokusika kufanele ibe ne-angle enkulu yokukhululeka.

Pholisha indawo yokusebenza ukuze uqedele kangcono futhi unciphise ukwakheka kwezinto.

Yehlisa izinga lokuphakelayo ukuze uthuthukise ukunemba kokusikeka kokugcina (sebenzisa isilinganiso sokuphakelayo esingu-0.015 IPR ngokusikeka okungalungile kanye no-0.005 IPR ukuze uthole ukusikeka okunembile).

Lungisa i-clearance, i-side, nama-engeli e-rake ezintweni zepulasitiki.

I-CNC Milling

Ukugaya i-CNC kuhilela ukusebenzisa i-milling cutter ukuze ususe izinto ezibonakalayo ku-workpiece ukuze uthole ingxenye edingekayo. Kunemishini yokugaya ehlukene ye-CNC ehlukaniswe yaba izigayo ezi-3-axis kanye nezigayo ezinama-axis amaningi.

Ngakolunye uhlangothi, umshini wokugaya we-CNC we-3-eksisi ungahamba ngezimbazo ezintathu eziqondile (kwesokunxele kuye kwesokudla, emuva naphambili, phezulu naphansi). Ngenxa yalokho, ifaneleka kahle ekudaleni izingxenye ezinemiklamo elula. Ngakolunye uhlangothi, izigayo ze-multi-axis zingahamba ngama-eksisi angaphezu kwamathathu. Ngenxa yalokho, ilungele izingxenye zepulasitiki ze-CNC ezinamajiyometri ayinkimbinkimbi.

Kuneziqondiso ezimbalwa ongazisebenzisa ekugayweni kwe-CNC yepulasitiki, okuhlanganisa:

Mashini i-thermoplastic eqiniswe ngekhabhoni noma ingilazi enamathuluzi ekhabhoni.

Khulisa isivinini sokuphotha ngokusebenzisa izinsimbi.

Yehlisa ukugxila kwengcindezi ngokudala amakhona angaphakathi ayindilinga.

Ukupholisa ngqo kumzila ukuze uhlakaze ukushisa.

Khetha isivinini sokujikeleza.

Debur plastic izingxenye emva Milling ukuthuthukisa surface kokuqeda.

CNC Drilling

I-Plastiki CNC drilling ihlanganisa ukudala imbobo endaweni yokusebenza yepulasitiki usebenzisa i-drill efakwe i-drill bit. Usayizi we-drill bit kanye nokuma kwayo kunquma usayizi wembobo. Ngaphezu kwalokho, futhi idlala indima ekukhishweni kwe-chip. Izinhlobo zomshini wokubhoboza ongazisebenzisa zihlanganisa ibhentshi, eliqondile, ne-radial.

Kunemihlahlandlela eminingana ongayisebenzisa ekubholeni ipulasitiki ye-CNC, okuhlanganisa:

Qinisekisa ukuthi usebenzisa izinsimbi zokubhoboza ze-CNC ezicijile ukuze ugweme ukubeka ingcindezi kucezu lwepulasitiki.

Sebenzisa i-drill bit efanele. Isibonelo, i-drill bit engu-90 kuya ku-118° ene-engeli yodebe engu-9 kuya ku-15° ifaneleka ku-thermoplastic eminingi (nge-acrylic, sebenzisa i-rake engu-0°).

Qinisekisa ukukhishwa kwe-chip okulula ngokukhetha i-drill bit elungile.

Sebenzisa isistimu yokupholisa ukuze unciphise ukukhiqizwa okwengeziwe phakathi nenqubo yokwenza imishini.

Ukuze ususe i-CNC drill ngaphandle kokulimala, qinisekisa ukuthi ukujula kokumba kungaphansi kwezikhathi ezintathu noma ezine. i-diameter ye-drill. Futhi, yehlisa izinga lokuphakelayo lapho i-drill isicishe yaphuma kokubalulekile.

Okunye Okungenziwa Kumashini Yepulasitiki

Ngaphandle kwe-CNC plastic part machining, ezinye izinqubo ze-prototyping ezisheshayo zingasebenza njengezinye izindlela. Ezivamile zihlanganisa:

Ukubunjwa komjovo

Lena inqubo yokukhiqiza ngobuningi edumile yokusebenza ngezingcezu zepulasitiki. Ukubumba umjovo kubandakanya ukudala isikhunta kusuka ku-aluminium noma insimbi kuye ngezinto ezifana nokuphila isikhathi eside. Ngemva kwalokho, ipulasitiki encibilikisiwe ijovwa embotsheni yesikhunta, iphole futhi yakhe isimo esidingekayo.

Ukubumba komjovo wePlastiki kulungele kokubili i-prototyping kanye nokukhiqizwa kwezingxenye zangempela. Ngaphandle kwalokho, kuyindlela engabizi kakhulu efanelekayo izingxenye ezinemiklamo eyinkimbinkimbi futhi elula. Ngaphezu kwalokho, izingxenye ezibunjwe ngomjovo azidingi umsebenzi owengeziwe noma ukwelashwa kwendawo.

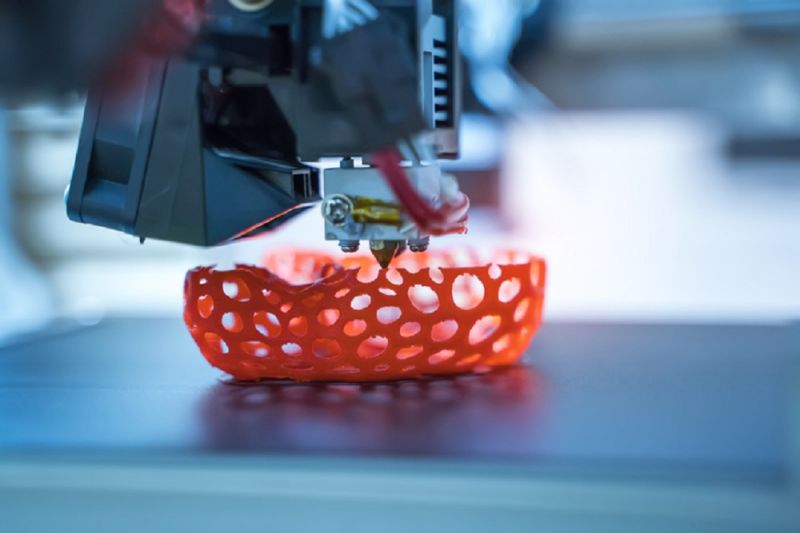

Ukuphrinta kwe-3D

Ukuphrinta kwe-3D kuyindlela evame kakhulu yokwenza i-prototyping esetshenziswa emabhizinisini amancane. Inqubo yokukhiqiza okungeziwe iyithuluzi lokulinganisa elisheshayo elihlanganisa ubuchwepheshe obufana ne-Stereolithography (SLA), i-Fused Deposition Modeling (FDM), kanye ne-Selective Laser Sintering (SLS) esetshenziselwa ukusebenza ku-thermoplastics efana neyiloni, i-PLA, i-ABS, ne-ULTEM.

Ubuchwepheshe ngabunye bubandakanya ukudala amamodeli edijithali e-3D nokwakha izingxenye ezifiselekayo ungqimba ngongqimba. Lokhu kufana ne-plastic CNC machining, nakuba idala ukumoshwa kwezinto ezincane, ngokungafani nalokhu kwakamuva. Ngaphezu kwalokho, iqeda isidingo sokusebenza kwamathuluzi futhi ifaneleka kakhulu ekwenzeni izingxenye ezinemiklamo eyinkimbinkimbi.

I-Vacuum Casting

I-vacuum casting noma i-polyurethane/urethane casting ifaka isikhunta se-silicon nama-resin ukwenza ikhophi yephethini eyinhloko. Inqubo ye-prototyping esheshayo ifaneleka ekudaleni ipulasitiki enekhwalithi ephezulu. Ngaphezu kwalokho, amakhophi ayasebenza ekuboneni imibono noma amaphutha edizayini yokuxazulula izinkinga.

Izicelo zezimboni zePlastiki CNC Machining

Imishini yePlastiki ye-CNC isetshenziswa kabanzi ngenxa yezinzuzo ezinjengokunemba, ukunemba, nokubekezelelana okuqinile. Izicelo ezijwayelekile zezimboni zenqubo zihlanganisa:

Imboni Yezokwelapha

I-CNC machining yepulasitiki iyasebenza njengamanje ekukhiqizeni izingxenye zemishini yezokwelapha njengezitho zokwenziwa nezinhliziyo zokwenziwa. Izinga layo eliphezulu lokunemba nokuphindaphinda liyivumela ukuthi ihlangabezane namazinga okuphepha aqinile adingwa imboni. Ngaphezu kwalokho, kunenqwaba yezinto ezibonakalayo, futhi ikhiqiza izimo eziyinkimbinkimbi.

Izingxenye Zezimoto

Bobabili abaklami bezimoto nonjiniyela basebenzisa imishini yePlastiki ye-CNC ukwenza izingxenye zezimoto zesikhathi sangempela kanye nama-prototypes. Ipulasitiki isetshenziswa kakhulu embonini ekwenzeni izingxenye zepulasitiki ze-cnc ezifana namadeshibhodi ngenxa yokungasindi kwayo, okunciphisa ukusetshenziswa kukaphethiloli. Ngaphezu kwalokho, ipulasitiki imelana nokugqwala nokuguga, okuhlangenwe nakho okuningi kwezingxenye zezimoto. Ngaphandle kwalokho, ipulasitiki iyabumbeka ibe yizimo eziyinkimbinkimbi kalula.

Izingxenye ze-Aerospace

Ukukhiqizwa kwengxenye ye-Aerospace kudinga indlela yokukhiqiza enembayo ephezulu kanye nokubekezelelana okuqinile. Ngenxa yalokho, imboni ikhetha ukwenza imishini ye-CNC ekuklameni, ekuhloleni, nasekwakheni izingxenye ezihlukene zomshini we-aerospace. Izinto zepulasitiki ziyasebenza ngenxa yokufaneleka kwazo kobunjwa obuyinkimbinkimbi, amandla, amakhemikhali angasindi naphezulu, nokumelana nokushisa.

Imboni Yezogesi

Imboni ye-elekthronikhi iphinde ithande ukwenziwa kwepulasitiki ye-CNC ngenxa yokunemba kwayo okuphezulu nokuphindaphinda. Okwamanje, le nqubo isetshenziselwa ukwenza izingxenye ze-elekthronikhi zomshini we-CNC ezifana nezibiyelo zocingo, amakhiphedi edivayisi, nezikrini ze-LCD.

Nini Ukukhetha Plastic CNC Machining

Ukukhetha ezinqubweni eziningi zokwenziwa kwepulasitiki okukhulunywe ngazo ngenhla kungaba inselele. Njengomphumela, ngezansi ukucatshangelwa okumbalwa okungakusiza ukuthi unqume ukuthi ukwenza imishini yepulasitiki ye-CNC kuyinqubo engcono yephrojekthi yakho:

Uma i-Plastic Prototype Design ene-Tight Tolerance

I-CNC plastic machining iyindlela engcono yokwenza izingxenye ezinemiklamo edinga ukubekezelelana okuqinile. Umshini wokugaya ojwayelekile we-CNC ungafinyelela ukubekezelelana okuqinile okungaba ngu-4 μm.

Uma I-Plastic Prototype Idinga Ikhwalithi Yokuqedwa Kwekhwalithi

Umshini we-CNC unikeza isiphetho esiphezulu sezinga eliphezulu okwenza kufaneke uma iphrojekthi yakho ingadingi inqubo eyengeziwe yokuqedela indawo. Lokhu akufani nokuphrinta kwe-3D, okushiya izimpawu zesendlalelo ngesikhathi sokuphrinta.

Uma I-Plastic Prototype Idinga Izinto Ezikhethekile

Imishini yePlastiki ye-CNC ingasetshenziselwa ukukhiqiza izingxenye ezivela ezinhlobonhlobo zezinto zepulasitiki, kufaka phakathi lezo ezinezakhiwo ezikhethekile ezifana nokumelana nokushisa okuphezulu, amandla aphezulu, noma ukumelana namakhemikhali aphezulu. Lokhu kuyenza ibe inketho efanelekile yokwakha ama-prototypes anezidingo ezikhethekile.

Uma Imikhiqizo Yakho Isesigabeni Sokuhlola

Imishini ye-CNC incike kumamodeli e-3D, okulula ukuwashintsha. Njengoba isigaba sokuhlola sidinga ukuguqulwa njalo, ukwenza imishini ye-CNC kuvumela abaklami nabakhiqizi ukuthi bakhe ama-prototypes asebenzayo epulasitiki ukuze bahlole futhi baxazulule amaphutha edizayini.

· Uma Udinga Inketho Yezomnotho

Njengezinye izindlela zokukhiqiza, ipulasitiki ye-CNC machining ifanele ukwenza izingxenye zibe nezindleko. Ipulasitiki ibiza kancane kunezinsimbi nezinye izinto, njengezinhlanganisela. Ngaphezu kwalokho, ukulawulwa kwezinombolo zekhompyutha kunembe kakhulu, futhi inqubo ifanele umklamo oyinkimbinkimbi.

Isiphetho

I-CNC plastic machining iyinqubo eyamukelwa kabanzi ezimbonini ngenxa yokunemba kwayo, isivinini, nokufaneleka kokwenza izingxenye ezibekezelelana ngokuqinile. Lesi sihloko sikhuluma ngezinto ezihlukahlukene zemishini ye-CNC ezihambisana nenqubo, amasu atholakalayo, nezinye izinto ezingasiza iphrojekthi yakho.

Ukukhetha indlela efanele yokwenza imishini kungaba inselele kakhulu, kudinge ukuthi ukhiphele ngaphandle kumnikezeli wesevisi wepulasitiki we-CNC. Kwa-GuanSheng sinikeza ngezinsizakalo zemishini yepulasitiki ye-CNC yangokwezifiso futhi ingakusiza wenze izingxenye ezihlukene ze-prototyping noma ukusetshenziswa kwesikhathi sangempela ngokusekelwe ezidingweni zakho.

Sinezinto eziningana zepulasitiki ezifanele umshini we-CNC ngenqubo yokukhetha eqinile futhi elula. Ngaphezu kwalokho, ithimba lethu lonjiniyela lingahlinzeka ngezeluleko zokukhetha izinto ezisebenzayo kanye nesiphakamiso sedizayini. Layisha idizayini yakho namuhla futhi uthole izingcaphuno ezisheshayo kanye nokuhlaziywa kwamahhala kwe-DfM ngentengo encintisanayo.

Isikhathi sokuthumela: Nov-13-2023