Ukukhethwa kohlobo olufanele lomshini kumashini we-CNC we-multi-axis kuphakathi kwezinqumo ezibaluleke kakhulu. Inquma amakhono jikelele enqubo, imiklamo engenzeka, kanye nezindleko eziphelele. 3-eksisi vs 4-eksisi vs 5-eksisi CNC machining kuyinkulumompikiswano edumile futhi impendulo efanele incike ezidingweni zephrojekthi.

Lo mhlahlandlela uzobheka izinto eziyisisekelo ze-multi-axis CNC machining futhi uqhathanise i-3-eksisi, 4-eksisi, kanye ne-5-eksisi CNC machining ukuze usize ekwenzeni ukukhetha okufanele.

Isingeniso se-3-Axis Machining

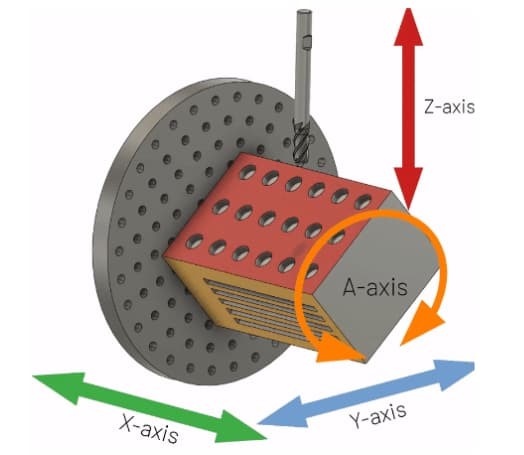

I-spindle ihamba ngokuzungeza ngomugqa ngo-X, Y, no-Z izikhombisi-ndlela futhi ucezu lokusebenza ludinga izinto ezilubamba endizeni eyodwa. Inketho yokusebenza ezindizeni eziningi ingenzeka emishinini yesimanje. Kodwa zidinga izinto ezikhethekile ezibiza kancane ukuzenza futhi zidle isikhathi esiningi.

Kukhona, nokho, ukulinganiselwa okuthile kulokho 3-eksisi CNCs angakwenza futhi. Izici eziningi azikwazi ukusebenza ngokwezomnotho, ngaphandle kwezintengo ezihambisanayo zama-CNC ama-3-eksisi, noma azinakwenzeka. Isibonelo, imishini ye-axis engu-3 ayikwazi ukudala izici ezinama-engeli nanoma yini ekuhlelo lokuxhumanisa i-XYZ.

Ngokuphambene, imishini ye-3-eksisi ingakha izici ezingaphansi. Kodwa-ke, badinga ama-pre-requites ambalwa kanye nabasiki abakhethekile njenge-T-slot kanye nabasiki be-Dovetail. Ukufeza lezi zidingo ngezinye izikhathi kungase kunyuse amanani entengo futhi ngezinye izikhathi kuba namandla kakhulu ukukhetha isixazululo sokugaya se-CNC esingu-4-eksisi noma esingu-5.

Isingeniso se-4-Axis Machining

Imishini ye-4-axis ithuthuke kakhulu kunozakwabo be-3-eksisi. Ngaphezu kokunyakaza kwethuluzi lokusika ezindizeni ze-XYZ, zivumela i-workpiece ukuthi ijikeleze ku-axis ye-Z futhi. Ukwenza kanjalo kusho ukuthi i-4-axis milling ingasebenza ezinhlangothini eziningi ezifika kwezi-4 ngaphandle kwezidingo ezikhethekile ezifana nokulungiswa okuhlukile noma amathuluzi okusika.

Njengoba kushiwo ngaphambili, i-eksisi eyengeziwe kule mishini iyenza ibe namandla ngokwezomnotho kwezinye izimo lapho imishini ye-3-axis ingathola umsebenzi, kodwa ngezidingo ezikhethekile. Izindleko ezengeziwe ezidingekayo ukuze kwenziwe ukulungiswa okufanele namathuluzi okusika ku-axis engu-3 zidlula umehluko wezindleko phakathi kwemishini ye-4-eksisi kanye ne-3-eksisi. Ngaleyo ndlela ibenza babe ukukhetha okusebenzayo kwamanye amaphrojekthi.

Ngaphezu kwalokho, esinye isici esibalulekile sokugaya i-4-axis yikhwalithi iyonke. Njengoba le mishini ingasebenza ezinhlangothini ezi-4 ngesikhathi esisodwa, ukusetha kabusha i-workpiece kuma-fixtures akudingekile. Ngaleyo ndlela kunciphisa amathuba amaphutha omuntu kanye nokwenza ngcono ukunemba okuphelele.

Namuhla, kunezinhlobo ezimbili zemishini ye-CNC ye-4-eksisi; okuqhubekayo kanye nenkomba.

Ukucutshungulwa okuqhubekayo kuvumela ithuluzi lokusika kanye ne-workpiece ukuhamba ngesikhathi esifanayo. Lokhu kusho ukuthi umshini ungakwazi ukusika impahla ngenkathi ujikeleza. Ngaleyo ndlela kwenza ama-arcs ayinkimbinkimbi namajamo afana nama-helix alula kakhulu ukuwenza.

I-Indexing machining, ngakolunye uhlangothi, isebenza ngezigaba. Ithuluzi lokusika liyama uma ucezu lokusebenza luqala ukuzungeza indiza engu-Z. Lokhu kusho ukuthi imishini yokukhomba ayinawo amandla afanayo ngoba ayikwazi ukudala ama-arcs ayinkimbinkimbi namajamo. Okuwukuphela kwenzuzo ukuthi i-workpiece manje isingenziwa ngomshini ezinhlangothini ezi-4 ezihlukene ngaphandle kokudinga noma yiziphi izinto ezikhethekile ezibalulekile emshinini we-3-eksisi.

Isingeniso se-5-Axis Machining

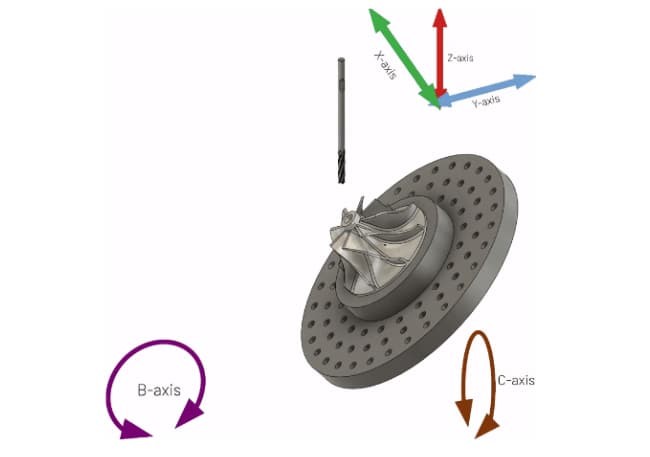

Imishini ye-5-axis ithatha izinto isinyathelo esisodwa ukuya phambili futhi ivumela ukujikeleza ezindizeni ezimbili. Lokhu kuzungezisa kwe-multi-axis kanye nekhono lethuluzi lokusika lokuhamba libheke ezinhlangothini ezintathu yizimfanelo ezimbili ezibalulekile ezenza kube nokwenzeka ngale mishini ukuphatha imisebenzi eyinkimbinkimbi kakhulu.

Kunezinhlobo ezimbili zemishini ye-CNC ye-5-eksisi etholakala emakethe. 3+2-axis machining kanye nemishini eqhubekayo ye-5-eksisi. Zombili zisebenza kuzo zonke izindiza kodwa eyokuqala inemikhawulo efanayo kanye nesimiso sokusebenza njengomshini we-indexing 4-axis.

Imishini ye-CNC ye-axis engu-3+2 ivumela ukuzungeza ukuthi kuzimele komunye nomunye kodwa ikhawulela ukusetshenziswa kwazo zombili izindiza ezixhumanisa ngesikhathi esisodwa. Ngokuphambene, ukuqhubeka kwemishini ye-5-axis akuzi nemikhawulo enjalo. Ngaleyo ndlela kuvumela ukulawula okuphakeme kanye nekhono lomshini kalula amajiyometri ayinkimbinkimbi kakhulu.

Umehluko Oyinhloko Phakathi Kwe-3, 4, 5 Axis CNC Machining

Ukuqonda izinto eziyinkimbinkimbi kanye nemikhawulo yohlobo lwemishini ye-CNC kubalulekile ekuqinisekiseni ibhalansi engcono kakhulu phakathi kwezindleko, isikhathi, kanye nekhwalithi yenqubo.

Njengoba kushiwo ngaphambili, amaphrojekthi amaningi azobiza kakhulu ekugayweni kwe-axis engu-3 ngendlela eyongayo ngenxa yobunkimbinkimbi obuhlobene nokulungisa nezinqubo. Ngokufanayo, ukukhetha nje ukugaya i-5-eksisi kuphrojekthi ngayinye kuzofana nokulwa namaphela ngesibhamu somshini. Akuzwakali kusebenza kahle, akunjalo?

Yingakho kubalulekile ukuqonda umehluko omkhulu phakathi kwe-3-eksisi, 4-eksisi, kanye ne-5-eksisi machining. Ukwenza kanjalo kungaqinisekisa ukuthi uhlobo olungcono kakhulu lomshini lukhethwa kunoma iyiphi iphrojekthi ngaphandle kokuyekethisa kumapharamitha wekhwalithi ebalulekile.

Nazi umehluko omkhulu phakathi kwezinhlobo ze-CNC machining.

Isimiso Sokusebenza

Umgomo wokusebenza kwawo wonke ama-CNC machining uyafana. Ithuluzi lokusika eliholwa yikhompuyutha lizungeza ucezu lokusebenza ukususa impahla. Ngaphezu kwalokho, yonke imishini ye-CNC isebenzisa ama-M-Codes noma ama-G-Codes ukuze ichaze ukunyakaza kwethuluzi okuhlobene nendawo yokusebenza.

Umehluko uza emandleni engeziwe okuzungeza mayelana nezindiza ezahlukene. Kokubili i-4-eksisi kanye ne-5-eksisi ye-CNC milling ivumela ukuzungezisa mayelana nezixhumanisi ezihlukene futhi le khwalithi iphumela ekudalweni komumo oyinkimbinkimbi kalula.

Ukunemba Nokunemba

Imishini ye-CNC iyaziwa ngokunemba kwayo nokubekezelelana okuphansi. Kodwa-ke, uhlobo lwe-CNC luthinta ukubekezelelana kokugcina komkhiqizo. I-CNC ye-3-eksisi, nakuba inembe kakhulu, izoba namathuba amaningi okuba namaphutha angahleliwe ngenxa yokumiswa kabusha okungaguquguquki kwesiqeshana sokusebenza. Ezinhlelweni eziningi, le mikhawulo yephutha ayinaki. Kodwa-ke, ezinsizeni ezibucayi eziphathelene ne-aerospace nezinhlelo zokusebenza zezimoto, ngisho nokuchezuka okuncane kakhulu kungabangela izinkinga.

Kokubili imishini ye-CNC ye-4-eksisi kanye ne-5-eksisi ayinayo leyo nkinga njengoba ingadingi ukumiswa kabusha. Bavumela ukusika ezindizeni eziningi endaweni eyodwa. Ngaphezu kwalokho, kubalulekile ukuqaphela ukuthi lona ukuphela komthombo wokungafani kwikhwalithi ye-3-axis machining futhi. Ngaphandle kwalokhu, ikhwalithi iyonke mayelana nokunemba nokunemba ihlala injalo.

Izinhlelo zokusebenza

Kunokusebenzisa imboni yonkana, umehluko ohlotsheni lwe-CNC uphathelene nemvelo yomkhiqizo. Isibonelo, umehluko phakathi kwemikhiqizo yokugaya engu-3-eksisi, 4-eksisi, kanye ne-5-eksisi uzosuselwa kunkimbinkimbi iyonke yomklamo kunemboni ngokwayo.

Ingxenye elula yomkhakha we-aerospace ingathuthukiswa emshinini wama-axis angu-3 kuyilapho into eyinkimbinkimbi yanoma yimuphi omunye umkhakha ingase idinge ukusetshenziswa komshini we-4-eksisi noma 5-eksisi.

Izindleko

Izindleko ziphakathi komehluko oyinhloko phakathi kuka-3, 4, no-5-axis CNC milling. Imishini ye-3-axis ngokwemvelo yonga kakhulu ukuyithenga nokuyinakekela. Kodwa-ke, izindleko zokuzisebenzisa zincike ezintweni ezifana nezinhlelo nokutholakala kwabasebenzisi. Nakuba izindleko ezitholwe opharetha zihlala zifana esimweni semishini ye-4-eksisi kanye ne-5-eksisi, ukulungiswa kusathatha ingxenye enkulu yezindleko.

Ngakolunye uhlangothi, i-4 kanye ne-5-axis machining ithuthuke kakhulu kwezobuchwepheshe futhi inezici ezingcono. Ngakho-ke, ayabiza ngokwemvelo. Kodwa-ke, baletha amakhono amaningi etafuleni futhi bayisinqumo esisebenzayo ezimweni eziningi eziyingqayizivele. Enye yazo sekuxoxiwe ngayo ngaphambili lapho umklamo ngokwethiyori ungenzeka ngomshini we-axis engu-3 uzodinga ukulungiswa okuningi kwangokwezifiso. Ngaleyo ndlela kukhuphula izindleko zizonke kanye nokwenza imishini ye-4-eksisi noma i-5-axis ibe inketho esebenza kangcono.

Isikhathi esiholayo

Uma kuziwa ezikhathini zokuhola eziphelele, imishini eqhubekayo ye-5-axis inikeza imiphumela engcono kakhulu iyonke. Bangakwazi ukucubungula ngisho nezimo eziyinkimbinkimbi kakhulu ngesikhathi esifushane ngenxa yokuntuleka kokumiswa kanye nomshini wesinyathelo esisodwa.

Imishini eqhubekayo ye-4-eksisi iza ngemva kwalokho njengoba ivumela ukuzungezisa ku-eksisi eyodwa futhi ingakwazi ukuphatha izici ze-angular ezihleliwe ekuhambeni okukodwa.

Ekugcineni, imishini ye-CNC ye-3-eksisi inesikhathi eside sokuhola ngoba ukusika kwenzeka ngezigaba. Ngaphezu kwalokho, imikhawulo yemishini ye-3-axis isho ukuthi kuzoba nokunye ukuhlelwa kabusha kwendawo yokusebenza, okungaholela ekwandeni kwezikhathi zokuhola eziphelele zanoma iyiphi iphrojekthi.

3 Axis vs 4 Axis vs 5 Axis Milling, Yikuphi Okungcono?

Ekwenziweni, ayikho into efana nendlela engcono kakhulu noma isixazululo esilingana konke. Ukukhetha okufanele kuncike ebunkingeni bephrojekthi, isabelomali sisonke, isikhathi, kanye nezidingo zekhwalithi.

3-eksisi vs 4-eksisi vs 5-eksisi, konke kunokuhle nokubi. Ngokwemvelo, i-axis engu-5 ingakha amajiyometri e-3D ayinkimbinkimbi, kuyilapho i-axis engu-3 ingakhipha izingcezu ezilula ngokushesha nangokuqhubekayo.

Ukufingqa, ayikho impendulo yombuzo wokuthi iyiphi inketho engcono. Noma iyiphi indlela yomshini eletha ibhalansi ephelele phakathi kwezindleko, isikhathi, nemiphumela ingaba inketho efanelekile yephrojekthi ethile.

Funda kabanzi: I-CNC Milling vs CNC Turning: Yikuphi Okulungile Ukukhetha

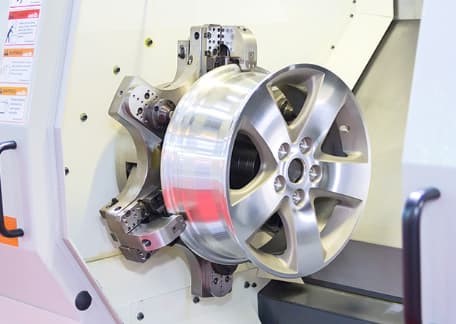

Qala amaphrojekthi akho nge-Guansheng's CNC Machining Services

Kunoma iyiphi iphrojekthi noma ibhizinisi, uzakwethu wokukhiqiza olungile angaba umehluko phakathi kwempumelelo nokwehluleka. Ukukhiqiza kuyingxenye ebalulekile yenqubo yokuthuthukiswa komkhiqizo futhi ukukhetha okufanele kuleso sigaba kungahamba ibanga elide ekwenzeni umkhiqizo usebenze. I-Guangsheng iyindlela ekahle yokukhiqiza yanoma yisiphi isimo ngenxa yokugcizelela kwayo ukuletha okuhle kakhulu ngokungaguquguquki okukhulu.

Ifakwe ngendawo yesimanjemanje kanye nethimba elinolwazi, i-Guangsheng ingakwazi ukuphatha zonke izinhlobo zemisebenzi yemishini ye-3-eksisi, 4, noma 5-eksisi. Ngokuhlola ikhwalithi eqinile endaweni, singaqinisekisa ukuthi izingxenye zokugcina zihlangabezana nazo zonke izinhlobo zokuhlolwa kwekhwalithi ngaphandle kokwehluleka.

Ngaphezu kwalokho, okwenza i-Guangsheng ihluke izikhathi zayo zokuhola ezisheshayo nezintengo ezincintisana kakhulu emakethe. Ngaphezu kwalokho, inqubo ibuye ithuthukiswe ukuze kube lula ikhasimende. Vele ulayishe kalula imiklamo ukuze uthole ukuhlaziywa kwe-DFM okuphelele kanye nekhwothi esheshayo ukuze uqalise.

Izixazululo ezizenzakalelayo neziku-inthanethi ziyizihluthulelo zekusasa lokukhiqiza futhi uGuangsheng uyakuqonda lokho. Yingakho yonke into oyoyidinga ukuze uthole imiphumela ehamba phambili ingukuchofoza nje.

Isiphetho

Wonke ama-CNC angu-3, 4, kanye nama-5-eksisi ahlukile futhi uhlobo ngalunye luza namandla noma ubuthakathaka balo. Ukukhetha okulungile, nokho, kuza ezidingweni ezihlukile zephrojekthi kanye nezidingo zayo. Akukho ukukhetha okulungile ekukhiqizeni. Indlela efanele ukuthola inhlanganisela engcono kakhulu yekhwalithi, izindleko, nesikhathi. Okuthile zontathu izinhlobo ze-CNC engakwazi ukuletha ngokusekelwe ezidingweni zephrojekthi ethile.

Isikhathi sokuthumela: Nov-29-2023