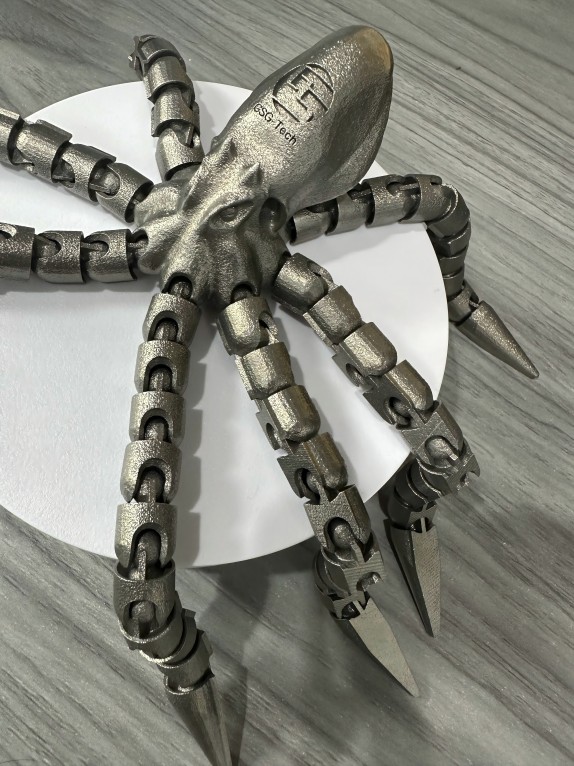

Muva nje, senze umboniso wensimbiUkuphrinta kwe-3D, futhi sayiqeda ngempumelelo kakhulu, ngakho-ke iyini insimbiUkuphrinta kwe-3D? Yiziphi izinzuzo nezingozi zalo?

Ukuphrinta kwe-Metal 3D kuwubuchwepheshe bokukhiqiza okungeziwe obakha izinto ezinezinhlangothi ezintathu ngokwengeza ungqimba lwensimbi ngongqimba. Nasi isingeniso esiningiliziwe sokuphrinta kwe-3D kwensimbi:

Isimiso sobuchwepheshe

I-selective laser sintering (SLS) : Ukusetshenziswa kwemishayo ye-laser yamandla aphezulu ukuncibilika ngokukhetha kanye nezimpushana zensimbi ze-sinter, ukushisisa into eyimpushana ibe izinga lokushisa elingaphansi kancane kwephuzu layo lokuncibilika, ukuze izibopho zensimbi phakathi kwezinhlayiya zempushana zakheke, ngaleyo ndlela kwakhiwe ungqimba lwento ngongqimba. Enqubweni yokunyathelisa, ungqimba olufanayo lwempushana yensimbi luqala lubekwe endaweni yokunyathelisa, bese ugongolo lwe-laser luskena impushana ngokuvumelana nokuma kwesigaba esiphambanayo sento, ukuze impushana eskeniwe inyibilike futhi iqine ndawonye, ngemva kokuphothulwa kongqimba lokunyathelisa, ipulatifomu yehla ibanga elithile, bese isakaza ungqimba olusha lwempushana, phinda le nqubo ephrintiwe ngenhla kuze kube yilapho yonke into ephrintiwe.

I-Selective Laser Melting (SLM) : Ngokufanayo ne-SLS, kodwa ngamandla e-laser aphezulu, impushana yensimbi ingancibilika ngokuphelele ukuze yakhe isakhiwo esiminyene, ukuminyana okuphezulu kanye nezakhiwo ezingcono zemishini zingatholakala, futhi amandla nokunemba kwezingxenye zensimbi eziphrintiwe kuphakeme, eduze noma kudlule ngisho nezingxenye ezikhiqizwa inqubo yokukhiqiza yendabuko. Ilungele ukukhiqiza izingxenye ze-aerospace, imishini yezokwelapha kanye neminye imikhakha edinga ukunemba okuphezulu nokusebenza.

I-Electron beam melting (EBM) : Ukusetshenziswa kwemishayo ye-electron njengomthombo wamandla wokuncibilikisa izimpushana zensimbi. I-electron beam inezici zokuminyana kwamandla aphezulu kanye nesivinini esikhulu sokuskena, esingancibilikisa ngokushesha impushana yensimbi futhi ithuthukise ukusebenza kahle kokunyathelisa. Ukuphrinta endaweni ye-vacuum kungagwema ukusabela kwezinto zensimbi nge-oxygen phakathi nenqubo yokunyathelisa, efanelekile ukuphrinta i-titanium alloy, i-alloy-based alloy nezinye izinto zensimbi ezizwelayo ku-oxygen okuqukethwe, evame ukusetshenziswa endaweni ye-aerospace, imishini yezokwelapha kanye nezinye izinkambu eziphezulu.

I-Metal Material Extrusion (ME) : Indlela yokukhiqiza esekelwe kwi-Material extrusion, ngekhanda le-extrusion ukuze kukhishwe impahla yensimbi ngendlela kasilika noma yokunamathisela, futhi ngesikhathi esifanayo ukushisa nokwelapha, ukuze kuzuzwe ungqimba ngokunqwabelana kongqimba. Uma kuqhathaniswa nobuchwepheshe bokuncibilika kwe-laser, izindleko zokutshala izimali ziphansi, zivumelana nezimo futhi zifaneleka, ikakhulukazi ezifanele ukuthuthukiswa kwangaphambi kwesikhathi endaweni yamahhovisi kanye nendawo yezimboni.

Izinto ezivamile

Ingxubevange ye-Titanium: inezinzuzo zamandla aphezulu, ukuminyana okuphansi, ukumelana nokugqwala okuhle kanye ne-biocompatibility, isetshenziswa kabanzi ku-aerospace, imishini yezokwelapha, ezezimoto neminye imikhakha, njengama-blade enjini yendiza, amalunga okwenziwa nezinye izingxenye zokukhiqiza.

Insimbi engagqwali: inokumelana nokugqwala okuhle, izakhiwo zemishini kanye nezakhiwo zokucubungula, izindleko eziphansi, ingenye yezinto ezivame ukusetshenziswa ekunyatheliseni kwensimbi ye-3D, ingasetshenziswa ukwenza izingxenye ezihlukahlukene zemishini, amathuluzi, amadivaysi ezokwelapha nokunye.

Ingxubevange ye-Aluminium: ukuminyana okuphansi, amandla aphezulu, ukuguquguquka okuhle kokushisa, okufanelekile ukukhiqiza izingxenye ezinezidingo zesisindo esikhulu, njenge-automobile engine cylinder block, izingxenye zesakhiwo se-aerospace, njll.

Ingxubevange esekelwe ku-nickel: enamandla aphezulu okushisa aphezulu, ukumelana nokugqwala kanye nokumelana ne-oxidation, ivamise ukusetshenziswa ekwenzeni izingxenye zokushisa okuphezulu njengezinjini zezindiza nezinjini zegesi.

inzuzo

Izinga eliphakeme lenkululeko yokuklama: Ikhono lokufeza ukukhiqizwa kobunjwa obuyinkimbinkimbi kanye nezakhiwo, njengezakhiwo ze-lattice, izakhiwo ezithuthukisiwe ze-topologically, njll, okunzima noma okungenakwenzeka ukufeza ezinqubweni zokukhiqiza zendabuko, inikeza isikhala esikhulu sokusungula umklamo womkhiqizo, futhi ingakhiqiza izingxenye ezilula, ezisebenza kahle kakhulu.

Yehlisa inani lezingxenye: izingxenye eziningi zingahlanganiswa zibe zizonke, ukunciphisa ukuxhuma kanye nenqubo yokuhlanganisa phakathi kwezingxenye, ukuthuthukisa ukusebenza kahle kokukhiqiza, ukunciphisa izindleko, kodwa futhi kuthuthukise ukuthembeka nokuzinza komkhiqizo.

I-prototyping esheshayo: Ingakhiqiza i-prototype yomkhiqizo ngesikhathi esifushane, isheshise umjikelezo wokuthuthukiswa komkhiqizo, yehlise izindleko zocwaningo nentuthuko, futhi isize amabhizinisi ukuletha imikhiqizo emakethe ngokushesha.

Ukukhiqizwa okwenziwe ngokwezifiso: Ngokwezidingo zomuntu ngamunye zamakhasimende, imikhiqizo eyingqayizivele ingenziwa ukuze ihlangabezane nezidingo ezikhethekile zamakhasimende ahlukene, afanele izimila zezokwelapha, ubucwebe nezinye izinkambu ezenziwe ngokwezifiso.

Umkhawulo

Izinga eliphezulu eliphansi: Ubulukhuni obungaphezulu bezingxenye zensimbi eziphrintiwe buphakeme ngokuqhathaniswa, futhi ukwelapha ngemva kokwelashwa kuyadingeka, njengokugaya, ukupholisha, ukuqhunyiswa kwesihlabathi, njll., ukuze kuthuthukiswe ukuphela kwendawo, ukwandisa izindleko zokukhiqiza nesikhathi.

Ukukhubazeka kwangaphakathi: kungase kube khona ukukhubazeka kwangaphakathi okufana nama-pores, izinhlayiya ezingaxutshiwe, kanye nokuhlanganiswa okungaphelele ngesikhathi senqubo yokunyathelisa, okuthinta izakhiwo zemishini yezingxenye, ikakhulukazi ekusetshenzisweni komthwalo ophezulu kanye nomthwalo we-cyclic, kuyadingeka ukunciphisa ukuvela kweziphambeko zangaphakathi ngokuthuthukisa imingcele yenqubo yokunyathelisa nokusebenzisa izindlela ezifanele emva kokucubungula.

Imikhawulo yezinto ezibonakalayo: Nakuba izinhlobo zezinto zokunyathelisa zensimbi ze-3D ezitholakalayo zanda, kusenemikhawulo ethile yezinto ezibonakalayo uma kuqhathaniswa nezindlela zokukhiqiza ezivamile, futhi ezinye izinto zensimbi ezisebenza kahle zinzima kakhulu ukuziphrinta futhi izindleko ziphezulu.

Izindleko zezindleko: Izindleko zemishini yokunyathelisa ye-3D yensimbi nezinto zokwakha ziphakeme kakhulu futhi isivinini sokunyathelisa sihamba kancane, esingabizi njengezinqubo zokukhiqiza zendabuko zokukhiqiza okukhulu, futhi okwamanje zifaneleka kakhulu inqwaba encane, ukukhiqizwa okwenziwe ngokwezifiso kanye nezindawo ezinokusebenza komkhiqizo ophezulu kanye nezidingo zekhwalithi.

Ubunkimbinkimbi bobuchwepheshe: Ukuphrinta kwe-Metal 3D kuhilela imingcele yenqubo eyinkimbinkimbi kanye nokulawulwa kwenqubo, okudinga ama-opharetha angochwepheshe nokusekelwa kobuchwepheshe, futhi kudinga izinga eliphezulu lobuchwepheshe nolwazi lwabaqhubi.

Inkambu yohlelo lokusebenza

I-Aerospace: Isetshenziselwa ukwakha ama-aero-engine blades, ama-turbine discs, izakhiwo zamaphiko, izingxenye zesathelayithi, njll., ezinganciphisa isisindo sezingxenye, ukuthuthukisa ukusebenza kahle kukaphethiloli, ukunciphisa izindleko zokukhiqiza, nokuqinisekisa ukusebenza okuphezulu nokuthembeka kwezingxenye.

Imoto: Khiqiza ibhulokhi yesilinda yenjini yemoto, igobolondo lokudlulisa, izingxenye zesakhiwo ezingasindi, njll., ukuze kuzuzwe umklamo ongasindi wezimoto, uthuthukise ukonga kukaphethiloli nokusebenza.

Ezokwelapha: Ukukhiqizwa kwemishini yezokwelapha, amalunga okwenziwa, ama-orthotics amazinyo, izinsiza zezokwelapha ezifakelwayo, njll., ngokusho komehluko ngamunye weziguli ezenziwe ngokwezifiso zokukhiqiza, ukuthuthukisa ukufaneleka kwemishini yezokwelapha kanye nemiphumela yokwelapha.

Ukukhiqiza isikhunta: Ukukhiqiza isikhunta somjovo, isikhunta se-die casting, njll., ukunciphisa umjikelezo wokukhiqiza isikhunta, ukunciphisa izindleko, ukuthuthukisa ukunemba nokuba yinkimbinkimbi kwesikhunta.

I-elekthronikhi: Khiqiza ama-radiators, amagobolondo, amabhodi wesekethe wemishini ye-elekthronikhi, njll., ukuze kuzuzwe ukukhiqizwa okuhlanganisiwe kwezakhiwo eziyinkimbinkimbi, ukuthuthukisa ukusebenza kanye nomphumela wokushisa wokushisa wemishini kagesi.

Ubucwebe: Ngokusho kobuhlakani bomklami kanye nezidingo zekhasimende, ubucwebe obuhlukahlukene obuhlukile bungenziwa ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza kanye nokwenza kube ngokwakho umkhiqizo.

Isikhathi sokuthumela: Nov-22-2024