Izingxenye zegobolondo ezinkulu, ezinodonga oluncane zilula ukusonteka futhi ziwohloke ngesikhathi somshini. Kulesi sihloko, sizokwethula i-heat sink case yezingxenye ezinkulu nezincane ezinodonga ukuze sixoxe ngezinkinga zenqubo evamile yomshini. Ngaphezu kwalokho, siphinde sinikeze inqubo ethuthukisiwe nesisombululo sendawo. Ake sifinyelele kukho!

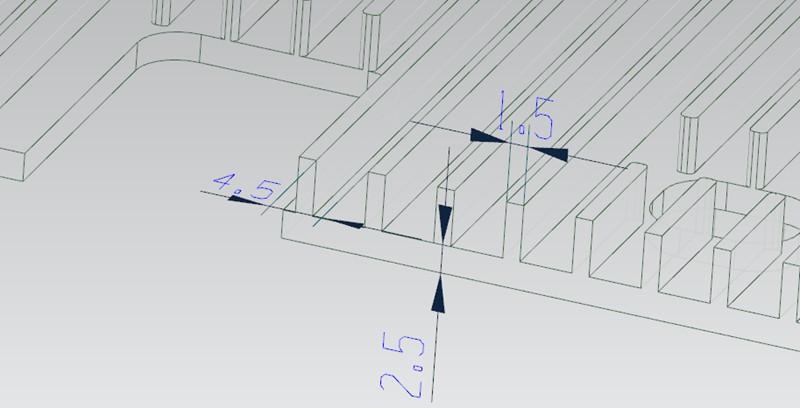

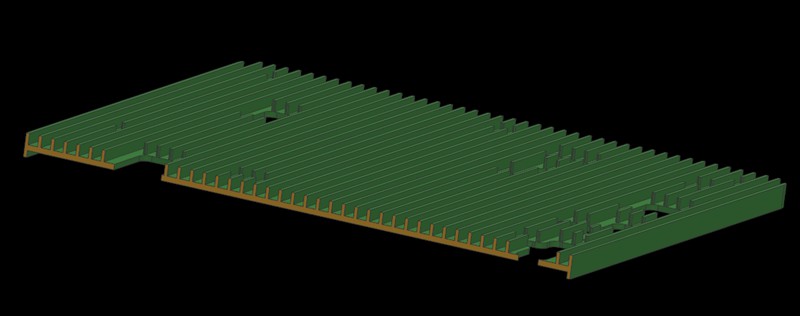

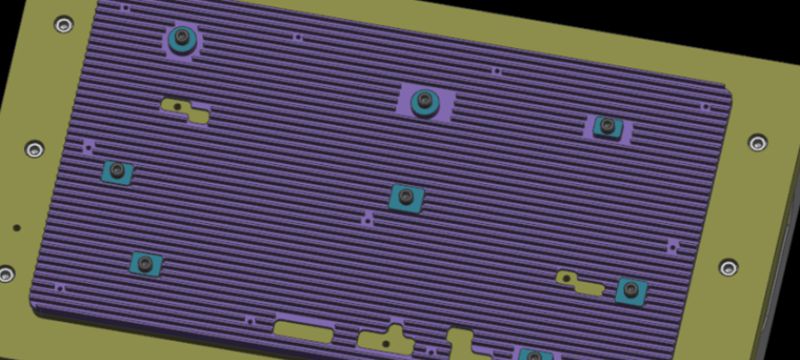

Icala limayelana nengxenye yegobolondo eyenziwe ngezinto ze-AL6061-T6. Nazi izilinganiso zayo eziqondile.

Ubukhulu bebonke: 455 * 261.5 * 12.5mm

Ukuqina Kwedonga Lokusekela: 2.5mm

Ubukhulu beSink Yokushisa: 1.5mm

Isikhala Sesinki Sokushisa: 4.5mm

Ukuzijwayeza Nezinselele Emizila Yenqubo Ehlukene

Ngesikhathi semishini ye-CNC, lezi zakhiwo zegobolondo ezinodonga oluncane zivame ukubangela izinkinga eziningi, ezifana ne-warping kanye nokuguqulwa. Ukuze sinqobe lezi zinkinga, sizama ukunikeza izinketho zenqubo ye-serval. Nokho, kusenezinkinga ezithile eziqondile zenqubo ngayinye. Nansi imininingwane.

Umzila wenqubo 1

Enqubweni yoku-1, siqala ngokwenza uhlangothi olungemuva (uhlangothi lwangaphakathi) lwe-workpiece bese sisebenzisa ukhonkolo ukuze sigcwalise izindawo ezinemigodi. Okulandelayo, sivumela uhlangothi olungemuva lube ireferensi, sisebenzisa i-glue kanye ne-tape enezinhlangothi ezimbili ukulungisa uhlangothi lwereferensi endaweni ukuze sishicilele uhlangothi lwangaphambili.

Nokho, kunezinkinga ezithile ngale ndlela. Ngenxa yendawo enkulu egcwele imbobo engemuva ohlangothini olungemuva, iglue kanye netheyiphu enezinhlangothi ezimbili azivikeleki ngokwanele isiqeshana sokusebenza. Kuholela ekujikeni phakathi kwe-workpiece kanye nokususwa kwezinto ezibonakalayo ohlelweni (okubizwa ngokuthi i-overcutting). Ngaphezu kwalokho, ukuntuleka kokuzinza kwe-workpiece nakho kuholela ekusebenzeni okuphansi kokucubungula kanye nephethini yommese ongaphezulu.

Umzila 2 wenqubo

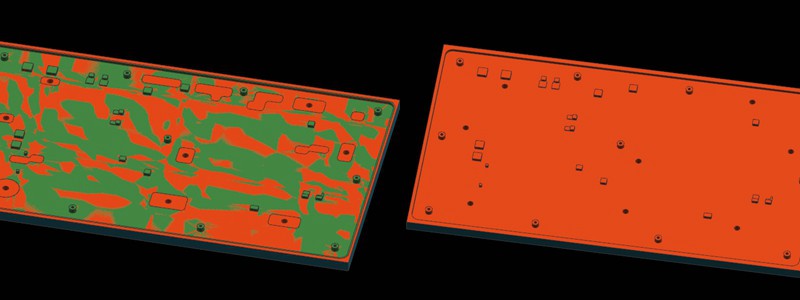

Ngenqubo yesi-2, sishintsha ukuhleleka komshini. Siqala nge-underside (uhlangothi lapho ukushisa kukhishwa khona) bese sisebenzisa i-backfilling ye-plaster yendawo engenalutho. Okulandelayo, sivumela uhlangothi lwangaphambili njengereferensi, sisebenzisa i-glue kanye ne-tape enezinhlangothi ezimbili ukuze silungise uhlangothi lwereferensi ukuze sikwazi ukusebenza ohlangothini olungemuva.

Nokho, inkinga ngale nqubo ifana nokucubungula umzila 1, ngaphandle kokuthi inkinga ishintshelwe ohlangothini olungemuva (uhlangothi lwangaphakathi). Futhi, lapho uhlangothi olungemuva lunendawo enkulu yokufaka i-backfill, ukusetshenziswa kweglue kanye ne-tape enezinhlangothi ezimbili akuhlinzeki ngokuzinza okuphezulu ku-workpiece, okuholela e-warping.

Umzila 3 wenqubo

Enqubweni yesi-3, sicabangela ukusebenzisa ukulandelana kwemishini yenqubo 1 noma inqubo 2. Bese kuthi inqubo yesibili yokubopha, sebenzisa ipuleti lokucindezela ukuze ubambe ucezu lokusebenza ngokucindezela phansi ku-perimeter.

Kodwa-ke, ngenxa yendawo enkulu yomkhiqizo, i-platen ikwazi kuphela ukumboza indawo yomjikelezo futhi ayikwazanga ukulungisa ngokugcwele indawo ephakathi nendawo yokusebenza.

Ngakolunye uhlangothi, lokhu kubangela ukuthi indawo ephakathi nendawo yokusebenza isabonakala kusukela ku-warping kanye ne-deformation, okuholela ekusithekeni ngokweqile endaweni emaphakathi yomkhiqizo. Ngakolunye uhlangothi, le ndlela yokwenza imishini izokwenza izingxenye zegobolondo le-CNC ezinodonga oluncane zibe buthaka kakhulu.

Umzila wenqubo 4

Ngenqubo yesi-4, sisebenza ngomshini ohlangothini olungemuva (uhlangothi lwangaphakathi) kuqala bese sisebenzisa i-vacuum chuck ukunamathisela indiza ehlanekezelwe ngomshini ukuze isebenze uhlangothi olungaphambili.

Kodwa-ke, endabeni yengxenye yegobolondo elinezindonga ezincane, kunezinhlaka eziqondile kanye ne-convex ohlangothini olungemuva lomsebenzi okufanele sizigweme lapho sisebenzisa ukumuncwa kwe-vacuum. Kodwa lokhu kuzodala inkinga entsha, izindawo ezigwenyiwe zilahlekelwa amandla azo okudonsa, ikakhulukazi ezindaweni ezine zamakhoneni kumjikelezo wephrofayili enkulu kakhulu.

Njengoba lezi zindawo ezingamuncwe zihambisana nohlangothi lwangaphambili (indawo esebenza ngomshini kuleli phuzu), ukugxuma kwethuluzi lokusika kungenzeka, okuholela kuphethini yamathuluzi edlidlizayo. Ngakho-ke, le ndlela ingaba nomthelela omubi kwikhwalithi yemishini kanye nokuqeda phezulu.

Umzila Wenqubo Olungiselelwe kanye Nesixazululo Sokulungisa

Ukuze kuxazululwe izinkinga ezingenhla, siphakamisa inqubo elungiselelwe elandelayo nezixazululo zesakhiwo.

Pre-machining Screw Through-holes

Okokuqala, sithuthukise umzila wenqubo. Ngesixazululo esisha, sicubungula uhlangothi olungemuva (uhlangothi lwangaphakathi) kuqala bese sifaka ngaphambili imbobo yesikulufu kwezinye izindawo ezizogcina zigojiwe. Inhloso yalokhu ukuhlinzeka ngendlela engcono yokulungisa nokubeka ezinyathelweni zomshini ezilandelayo.

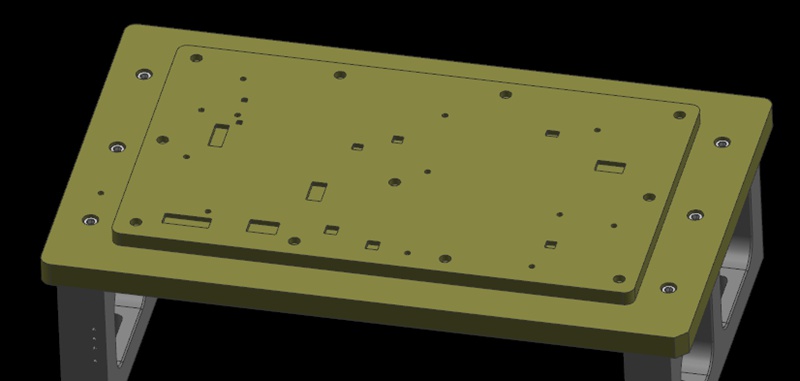

Biyela Indawo ezokwenziwa Umshini

Okulandelayo, sisebenzisa izindiza ezenziwe ngomshini ohlangothini olungemuva (uhlangothi lwangaphakathi) njengereferensi yomshini. Ngesikhathi esifanayo, sivikela i-workpiece ngokudlula isikulufu embotsheni engaphezulu ukusuka enqubweni yangaphambilini bese siyikhiya ku-fixture plate. Bese uzungeza indawo lapho isikulufu sikhiywe njengendawo ezokwenziwa ngomshini.

Ukulandelana Kwemishini nge-Platen

Ngesikhathi sokusebenza ngomshini, siqale sicubungule ezinye izindawo ngaphandle kwendawo ezokwenziwa ngomshini. Uma lezi zindawo sezishintshiwe, sibeka i-platen endaweni yomshini (i-platen idinga ukumbozwa ngeglue ukuze kuvinjelwe ukuchotshozwa kwendawo yomshini). Sibe sesisusa izikulufu ezisetshenziswe esinyathelweni sesi-2 bese siqhubeka nokwenza izindawo ezizokwenziwa ngomshini kuze kuqedwe wonke umkhiqizo.

Ngale nqubo ethuthukisiwe nesixazululo sokulungisa, singabamba ingxenye yegobolondo le-CNC enezindonga ezincane kangcono futhi sigweme izinkinga ezinjengokubhimba, ukuhlanekezela, nokusika ngokweqile. Izikulufu ezigxunyekiwe zivumela i-fixture plate ukuthi inamathele ngokuqinile kucezu lokusebenza, inikeze ukuma okuthembekile nokusekelwa. Ukwengeza, ukusetshenziswa kwepuleti lokucindezela ukufaka ingcindezi endaweni eyenziwe ngomshini kusiza ukugcina umsebenzi uzinzile.

Ukuhlaziywa Okujulile: Ungakugwema Kanjani Ukungqubuzana Nokuguquguquka?

Ukuzuza ukukhiqiza okuphumelelayo kwezakhiwo zegobolondo ezinkulu nezincane kudinga ukuhlaziywa kwezinkinga ezithile enqubweni yokwenza imishini. Ake sihlolisise ukuthi lezi zinselele zinganqotshwa kanjani ngokuphumelelayo.

Pre-machining Inner Side

Esinyathelweni sokuqala sokwenza imishini (ukwenza uhlangothi lwangaphakathi), impahla iyisiqephu esiqinile sezinto esinamandla amakhulu. Ngakho-ke, i-workpiece ayihlushwa ukungahambi kahle kwemishini njengokuguquguquka kanye ne-warping phakathi nale nqubo. Lokhu kuqinisekisa ukuzinza nokunemba lapho kwenziwa i-clamp yokuqala.

Sebenzisa Indlela Yokukhiya Nokucindezela

Ngesinyathelo sesibili (umshini lapho i-sink yokushisa ikhona), sisebenzisa indlela yokukhiya nokucindezela yokubopha. Lokhu kuqinisekisa ukuthi amandla okubamba aphakeme futhi asatshalaliswa ngokulinganayo endizeni eyinkomba esekelayo. Lokhu kubamba kwenza umkhiqizo uzinze futhi awujiki phakathi nayo yonke inqubo.

Isixazululo Esihlukile: Ngaphandle Kwesakhiwo Esingenalutho

Kodwa-ke, kwesinye isikhathi sihlangabezana nezimo lapho kungenzeki khona ukwenza isikulufu siphumele emgodini ngaphandle kwesakhiwo esingenalutho. Nasi esinye isixazululo.

Singakwazi ukuklama ngaphambili ezinye izinsika ngesikhathi somshini wohlangothi olungemuva bese sithepha kuzo. Phakathi nenqubo elandelayo yokwenza imishini, sinezikulufu ezidlula ohlangothini olungemuva lwe-fixture futhi sikhiye ucezu lokusebenza, bese senza umshini wendiza yesibili (uhlangothi lapho ukushisa kuchithwa khona). Ngale ndlela, singakwazi ukuqedela isinyathelo sesibili somshini ngokudlula okukodwa ngaphandle kokushintsha ipuleti phakathi. Ekugcineni, sengeza isinyathelo sokubopha kathathu futhi sisuse izinsika zenqubo ukuze siqedele inqubo.

Sengiphetha, ngokuthuthukisa inqubo kanye nesixazululo se-fixture, singakwazi ukuxazulula ngempumelelo inkinga ye-warping kanye nokuguqulwa kwezingxenye ezinkulu zegobolondo ezincane ngesikhathi somshini we-CNC. Lokhu akuqinisekisi kuphela izinga lomshini nokusebenza kahle kodwa futhi kuthuthukisa ukuzinza kanye nekhwalithi yobuso bomkhiqizo.