Izingxenye zensimbi ezinembayo zivame ukukhiqizwa kusetshenziswa ubuchwepheshe bemishini obunembayo obuhlukahlukene, kanti ukwenziwa kwe-CNC kuyindlela evamile. Ngokuvamile, izingxenye ezinembayo ngokuvamile zidinga amazinga aphezulu kukho kokubili ubukhulu nokubukeka.

Ngakho-ke, uma usebenzisa i-CNC machining metals njenge-aluminium nethusi, ukuvela kwamamaki amathuluzi nemigqa endaweni yomkhiqizo oqediwe kuyakhathaza. Lesi sihloko sixoxa ngezizathu ezibangela izimpawu zamathuluzi nemigqa ngesikhathi somshini wemikhiqizo yensimbi. Siphakamisa nezixazululo ezingaba khona.

I-Clamping Force Of Fixtures enganele

Izimbangela:Eminye imikhiqizo yensimbi yomgodi idinga ukusebenzisa izinto ze-vacuum, futhi ingase ibe nzima ukukhiqiza ukudonsa okwanele ngenxa yokuba khona kokungahambi kahle kwendawo, okuholela kumamaki amathuluzi noma imigqa.

Isixazululo:Ukuze unciphise lokhu, cabanga ngokushintsha usuka ekumunceni isivacu esilula uye ekumunceni nge-vacuum kuhlanganiswe nokucindezela noma ukwesekwa kwezinhlangothi. Noma, hlola ezinye izinketho zokulungisa ezisuselwe ezingxenyeni ezithile zezakhiwo, ulungise isisombululo senkinga ethile.

Izici Ezihlobene Nenqubo

Izimbangela:Izinqubo ezithile zokukhiqiza umkhiqizo zingase zibe nomthelela odabeni. Isibonelo, imikhiqizo efana namagobolondo angemuva e-tablet PC idlula ngokulandelana kwezinyathelo zomshini ezibandakanya ukubhoboza izimbobo eziseceleni okulandelwa yi-CNC milling emaphethelweni. Lokhu kulandelana kungaholela kumamaki amathuluzi aqaphelekayo lapho ukugaya kufinyelela ezindaweni zembobo eseceleni.

Isixazululo:Isibonelo esivamile sale nkinga senzeka lapho ingxubevange ye-aluminium ikhethelwa amagobolondo omkhiqizo we-elekthronikhi. Ukuyixazulula, inqubo ingashintshwa ngokufaka esikhundleni sokubhoboza kwembobo eseceleni kanye nokugaya ngokugaya kuphela kwe-CNC. Ngesikhathi esifanayo, ukuqinisekisa ukusebenzisana kwethuluzi okungaguquki kanye nokunciphisa ukusika okungalingani lapho kugaya.

Ukuhlelwa Okungenele Kokusebenzisana Kwendlela Yethuluzi

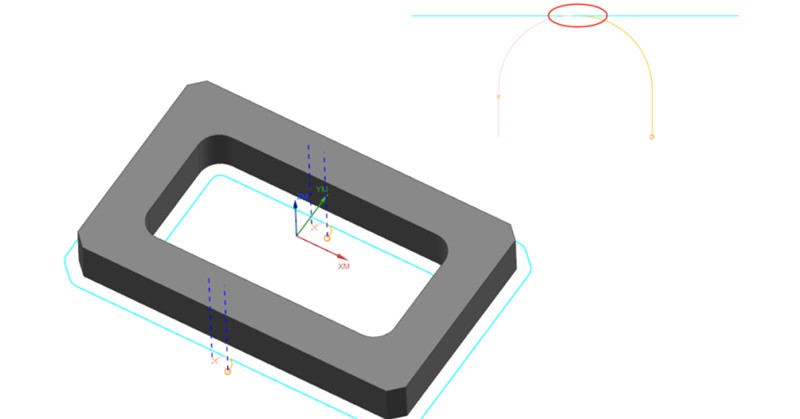

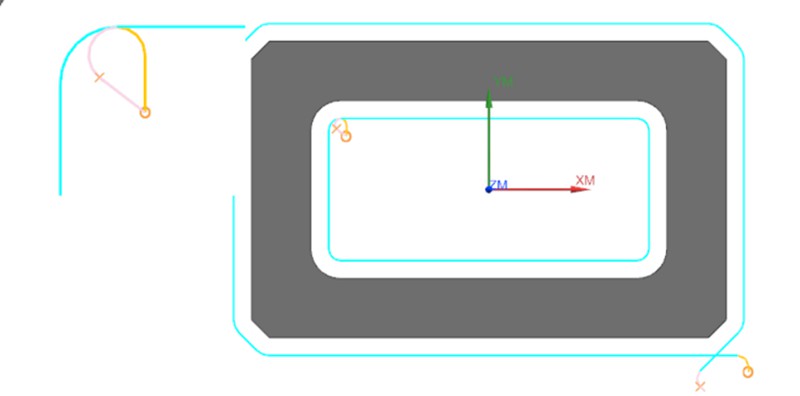

Izimbangela:Le nkinga ivamise ukuvela phakathi nesigaba somshini we-2D contour sokukhiqizwa komkhiqizo. Indlela yamathuluzi eklanywe kabi ohlelweni lwe-CNC, okushiya imikhondo ezindaweni zokungena nezokuphuma zethuluzi.

Isixazululo:Ukuze kubhekwane nenselele yokugwema izimpawu zamathuluzi ezindaweni zokungena nezokuphuma, indlela evamile ihlanganisa ukwethula ukugqagqana okuncane ebangeni lokusebenzelana kwamathuluzi (cishe u-0.2mm). Le nqubo isebenzela ukugwema ukunemba okungenzeka ekunembeni kwesikulufu sokuhola somshini.

Nakuba leli su livimbela ngokuphumelelayo ukwakheka kwamamaki amathuluzi, libangela isici somshini ophindaphindayo lapho impahla yomkhiqizo iyinsimbi ethambile. Ngenxa yalokho, lesi sigaba singabonisa ukuhlukahluka kokwakheka nombala uma kuqhathaniswa nezinye izindawo.

Amaphethini Esilinganiso Sezinhlanzi Ezindaweni Ezisesicaba Esenziwe Ngomshini

Izimbangela:Isikali sezinhlanzi noma amaphethini ayindilinga avela endaweni eyisicaba yomkhiqizo. Amathuluzi okusika asetshenziselwa ukucubungula izinsimbi ezithambile ezifana ne-aluminium/ithusi ngokuvamile izigayo ze-alloy material ezinemitshingo emi-3 kuya kwezi-4. Zinobunzima obusuka ku-HRC55 ukuya ku-HRC65. Lawa mathuluzi okusika enziwa kusetshenziswa unqenqema olungezansi lwethuluzi, futhi ingxenye engaphezulu ingase ithuthukise amaphethini esikali sezinhlanzi ahlukile, kube nomthelela ekubukekeni kwayo kukonke.

Isixazululo:Okuvame ukubonwa emikhiqizweni enezidingo zokucaba okuphezulu kanye nezindawo eziyisicaba ezinezakhiwo ezihlehlisiwe. Ikhambi ukushintshela kumathuluzi okusika enziwe ngezinto zedayimane zokwenziwa, esiza ukufeza ukuqedwa okubushelelezi kwendawo.

Ukuguga Nokugqokwa Kwezinsimbi

Izimbangela:Uphawu lwamathuluzi endaweni yomkhiqizo lubangelwa ukuguga nokuguga kwesisetshenziswa sokuphotha, amabheringi, nesikulufu somthofu. Ukwengeza, amapharamitha e-backlash yesistimu ye-CNC enganele anomthelela kumamaki amathuluzi aphinyiselwe, ikakhulukazi uma kwenziwa amakhona ayindilinga.

Isixazululo:Lezi zinkinga zisukela ezintweni ezihlobene nemishini futhi zingaxazululwa ngokulungiswa okuhlosiwe nokushintshwa.

Isiphetho

Ukuthola indawo ekahle ku-CNC machining metals kudinga izindlela eziwusizo. Kunezindlela ezihlukene zokugwema izimpawu zamathuluzi nemigqa ebandakanya inhlanganisela yokugcinwa kwemishini, izithuthukisi zezinto ezilungiswayo, ukulungiswa kwenqubo, nokuthuthukiswa kwezinhlelo. Ngokuqonda nokulungisa lezi zici, abakhiqizi bangaqinisekisa ukuthi izingxenye ezinembayo azifinyeleli nje kuphela imibandela yobukhulu kodwa futhi zibonisa izimfanelo zobuhle ezifiselekayo.